Precision Manufacturing, Empowering Medical Technology Innovation

Why Medical Device Companies Choose Voguc?

By choosing appropriate materials, we reduce production and manufacturing costs, allowing doctors and patients to enjoy medical services at a lower cost. Voguc is actively working to make healthcare more affordable.

We have advanced 5-axis CNC machines capable of producing versatile, aesthetically-focused, high-precision medical components that are trusted by Fortune 500 medical device companies, as well as medical device engineers and designers.

What Materials Work Best for Custom Medical Instruments?

Titanium and titanium alloys are mainly used in orthopedic surgery, especially in limb and cranial reconstruction, for the production of various fracture internal fixation devices, artificial joints, skull and dura, artificial heart valves, teeth, dental beds, brackets and crowns.

Cobalt alloys are more suitable for the manufacture of long-term implants with severe in vivo loading conditions, mainly used for the manufacture of artificial hip joints, knee joints, joint fasteners, bone plates, bone nails and bone pins.

Stainless steel is used for fracture avoidance medical devices: knives, scissors, hemostats, needles, artificial joints, internal fracture fixators, orthodontics, artificial heart valves, etc.

Medical precious metals are the general term for gold (An), silver (Ag), platinum (Pt) and their alloys. Because of their excellent electrical conductivity, they are often used to make implantable electrodes or electronic detection devices.

Polyethylene is among the top medical-grade plastics because of its cost-effectiveness, impact resistance, corrosion resistance and robust structural integrity during frequent sterilization cycles, making it suitable for the manufacture of prostheses.

Polypropylene is stress, crack, impact and fatigue resistant and is used in the manufacture of plastic components for medical devices such as disposable syringes, oxygenator membranes, prescription bottles, connectors and knuckle prostheses.

PVC materials are durable, strong and rigid. It is suitable for the manufacture of hemodialysis devices, catheters, cardiac catheters and prosthetic materials.

Polycarbonate has good heat resistance and biocompatibility and is suitable for the manufacture of medical components such as IV connectors for renal dialysis, cardiac surgery.

Medical Parts Applications

Voguc can supply you with high-quality medical plastic and metal materials. Regardless of the stages of processing, design, and development, the solutions and experience of our medical engineers can bring you efficient, comfortable and safe products and help you achieve higher product benefits.

- Bone Plates

- Screws

- Implant Roots

- Knife, Scissors

- Cardiovascular Stents

- Hemostat, Needle

Manufacturing Capacity of Medical Industry

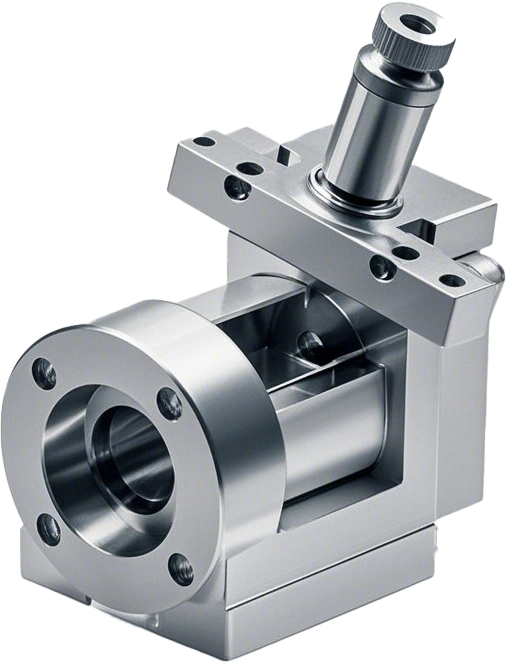

Most of the medical parts have the characteristics of small batch, multi-species, irregular shape, hard material, high surface finish, etc. These parts need strict precision manufacturing and quality control, such as orthopedic implants (mostly titanium alloy or stainless steel, with joint plates, artificial joints, bone nails, etc.), dental implants, pacemaker parts, etc.

CNC Machining Service

Tolerance down to ±0.01mm

• CNC Milling

• CNC Turning

• Surface Treatment

Sheet Metal Fabrication

Tolerance down to ±0.01mm

• Laser Cutting

• Stamping

• Bending

How does Voguc Innovate Medical Technologies?

Voguc implements product experimentation and development according to your design drawings, design concepts, specific functional or index requirements, and the whole process relies on the professional skills and valuable experience of our medical engineers.

The cost of acquiring a set of surgical instruments is generally quite high. Voguc strives to provide multiple options for customers to choose from, ensuring the most cost-effective solution.

Voguc can provide low-cost personalized component customization tailored to the specific needs of individual patients.

Voguc’s engineering team has 8 years of experience in machining medical device components, ensuring improved processing efficiency while maintaining product stability.

Voguc is actively developing more applicable new materials to enhance customer experience while contributing to environmental protection in a modest yet meaningful way.