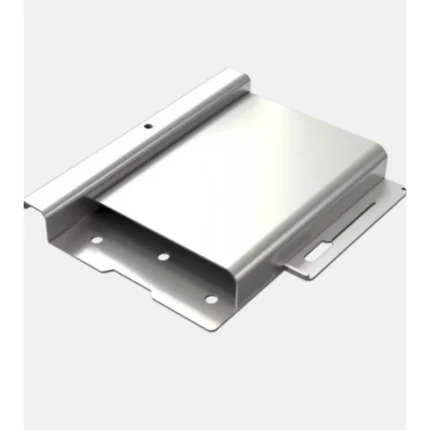

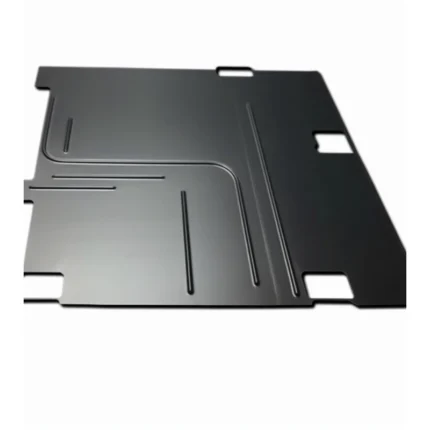

Superior Material Selection for Long-Lasting Performance

We use only the best materials—high-strength steel and alloys—to manufacture milled parts for automotive engines. These materials are chosen for their ability to withstand extreme temperatures and mechanical stress, ensuring long-lasting performance and engine efficiency. Whether it's for improved durability or reduced engine wear, our parts are built to last.

Precision Manufacturing for Optimal Engine Functionality

Each milled part is carefully crafted using advanced CNC machining techniques. This high-precision manufacturing ensures that each component fits perfectly within your engine, improving overall performance. The precision reduces friction, enhances engine efficiency, and extends the lifespan of your engine components.

Improved Engine Performance and Fuel Efficiency

Our milled automotive engine parts contribute to improved fuel efficiency and engine performance. By reducing friction and enhancing airflow, these parts help your engine run smoother, leading to better fuel economy and increased power. Whether you're aiming for better acceleration, higher torque, or longer engine life, our parts deliver the performance you need.

Custom Solutions for Specialized Engine Builds

We offer custom milled parts to meet the unique needs of your engine design. From custom sizes to specific material requirements, we collaborate with you to create parts that fit your exact specifications. This ensures your engine operates at its highest potential, with tailored components that enhance overall performance.

Cost-Effective and Reliable Solutions for Engine Manufacturers

Our milled parts provide reliable, high-performance solutions at a competitive price. We Voguc aim to provide high-quality components without compromising your budget. Whether you're producing standard automotive engines or specialized performance vehicles, our parts offer an economical and effective solution for your manufacturing needs.

Parameter of(Milled parts used in automotive engines)

| Item | Customized according to customer requirements |

| Volume | |

| Surface finish | |

| Material | |

| Weight | |

| Applicable standards | |

| Other requirements |

Advantage of (Milled parts used in automotive engines)

This component is used in automotive engines and must maintain high quality to help extend the engine's service life.

Image of (Milled parts used in automotive engines)

Looking for your inquiry of this (Milled parts used in automotive engines)

FAQ

A: We work with a wide range of metals and plastics, including aluminum, stainless steel, brass, copper, titanium, POM, and more.

A: Yes, we specialize in custom machining based on customer-provided drawings or 3D models.

A: We accept STEP, IGES, STL, PDF, and DWG formats.

A: Standard lead time is 7–15 working days, depending on part complexity and order quantity.

A: Yes, we provide anodizing, sandblasting, electroplating, powder coating, polishing, and more.

A: We do not have a strict MOQ—prototypes and small batches are welcome.

A: Yes, we offer mechanical assembly services if required.

Services

1. Quote within one business day upon receipt of drawings and requirements

2. Transparent production process, allowing you to monitor production progress at any time

3. Customizable shipping methods

Reviews

There are no reviews yet.