🛠️ High-Quality Manufacturing for Superior Performance

Using state-of-the-art manufacturing processes such as CNC machining, laser cutting, and stamping, our sheet metal parts are crafted with meticulous attention to detail. These methods ensure a perfect fit and long-lasting durability, which is essential for the functionality and safety of medical devices.

🌿 Biocompatible and Safe for Healthcare Use

Using materials are carefully selected to ensure biocompatibility and safety for healthcare applications. With a focus on quality and regulatory compliance, our sheet metal parts meet industry standards such as ISO 13485, guaranteeing that your medical devices are both safe and effective for patient care.|

💡 Custom Solutions for Every Medical Device Design

We can customize sheet metal parts to the unique specifications of your desired medical device. Regardless of the specific shape, size, or material type, our dedicated engineers will work closely with you to develop a part that meets your exact needs, enhancing the functionality and reliability of your product.

🌍 Compliant with Global Standards

Our sheet metal fabricated parts comply with global medical device standards and regulations. With years of experience in the medical manufacturing sector, we ensure that our parts not only meet but exceed industry expectations, ensuring your products are ready for worldwide markets.

🚀 Fast Lead Times and Competitive Pricing

We understand the importance of timely delivery in the medical industry. Our sheet metal parts for medical devices come with fast turnaround times and competitive pricing, making us the go-to partner for your production needs. From prototypes to full-scale production runs, we deliver consistent quality and on-time results.

Parameter of(Sheet metal fabricated parts for medical devices)

| Item | Customized according to customer requirements |

| Volume | |

| Surface finish | |

| Material | |

| Weight | |

| Applicable standards | |

| Other requirements |

Advantage of (Sheet metal fabricated parts for medical devices)

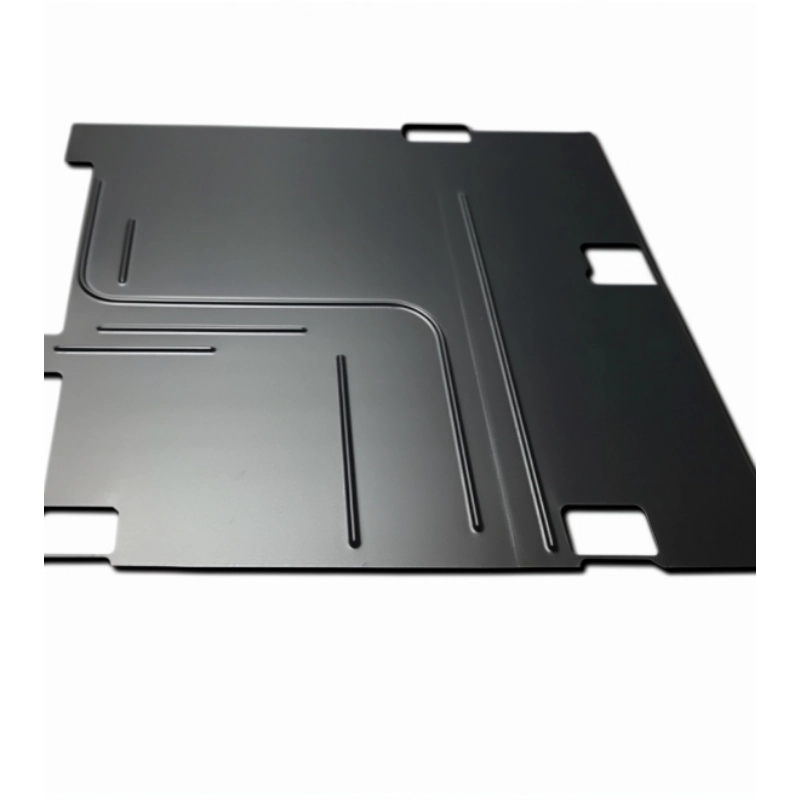

This component is used as the housing for medical devices and must maintain high quality to protect the internal precision parts.

Image of (Sheet metal fabricated parts for medical devices)

Looking for your inquiry of this (Sheet metal fabricated parts for medical devices)

FAQ

A: We work with a wide range of metals and plastics, including aluminum, stainless steel, brass, copper, titanium, POM, and more.

A: Yes, we specialize in custom machining based on customer-provided drawings or 3D models.

A: We accept STEP, IGES, STL, PDF, and DWG formats.

A: Standard lead time is 7–15 working days, depending on part complexity and order quantity.

A: Yes, we provide anodizing, sandblasting, electroplating, powder coating, polishing, and more.

A: We do not have a strict MOQ—prototypes and small batches are welcome.

A: Yes, we offer mechanical assembly services if required.

Services

1. Quote within one business day upon receipt of drawings and requirements

2. Transparent production process, allowing you to monitor production progress at any time

3. Customizable shipping methods

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Reviews

There are no reviews yet.