Quick-turn CNC machining is transforming modern manufacturing by delivering parts in record time without compromising quality. This rapid manufacturing method, also known as fast CNC manufacturing, combines advanced software, automated tool changes, and skilled programming to meet urgent production needs. Just like “lead-free compliance” is essential for electronics, CNC machining is essential for time-critical manufacturing.

Long Lead Times Delay Market Entry

Many companies lose market share because their prototypes take weeks to arrive. Traditional machining shops often have backlog issues and outdated scheduling. These delays push back product launches and reduce competitiveness.

Quick-turn CNC machining eliminates these bottlenecks. By streamlining workflow, manufacturers receive precision parts within days instead of weeks. This allows faster testing and quicker entry into the market.

Inflexible Production for Urgent Orders

Unexpected orders or design changes can cause serious stress for manufacturers. Traditional setups require long preparation before production can start.

Quick-turn CNC machining is built for flexibility. It allows rapid adaptation to urgent requests while keeping tolerance within ±0.01mm. As a result, companies can fulfill emergency orders without sacrificing quality.

High Costs of Production Delays

Every extra day in production costs money. Storage fees, idle labor, and missed deadlines all increase expenses.

By cutting production time by up to 50%, quick-turn CNC machining helps reduce these hidden costs. When orders are completed quickly, operational efficiency improves, and cash flow becomes more predictable.

Poor Supply Chain Coordination

Even with fast machining, poor logistics can cause delivery delays. Many companies overlook the importance of choosing a reliable logistics agent.

A good logistics partner ensures that parts produced with quick-turn CNC machining reach customers on time. They also provide shipment tracking and handle customs clearance for international deliveries.

Limited Capacity for Small-Batch Runs

Some manufacturers need small quantities fast. Traditional shops prioritize large orders, leaving smaller runs at the back of the queue.

Quick-turn CNC machining is ideal for small-batch production. It uses automated scheduling to prioritize speed, meaning even low-volume runs get delivered within tight deadlines.

Technical Solution: How Quick-Turn CNC Machining Achieves Speed

1. Automated CAM Programming

Quick-turn CNC machining uses advanced CAM software that auto-generates tool paths. This reduces programming time by up to 70%.

2. High-Speed Tooling and Spindle Technology

Machines operate with spindles reaching 15,000 RPM, enabling faster material removal without sacrificing surface finish.

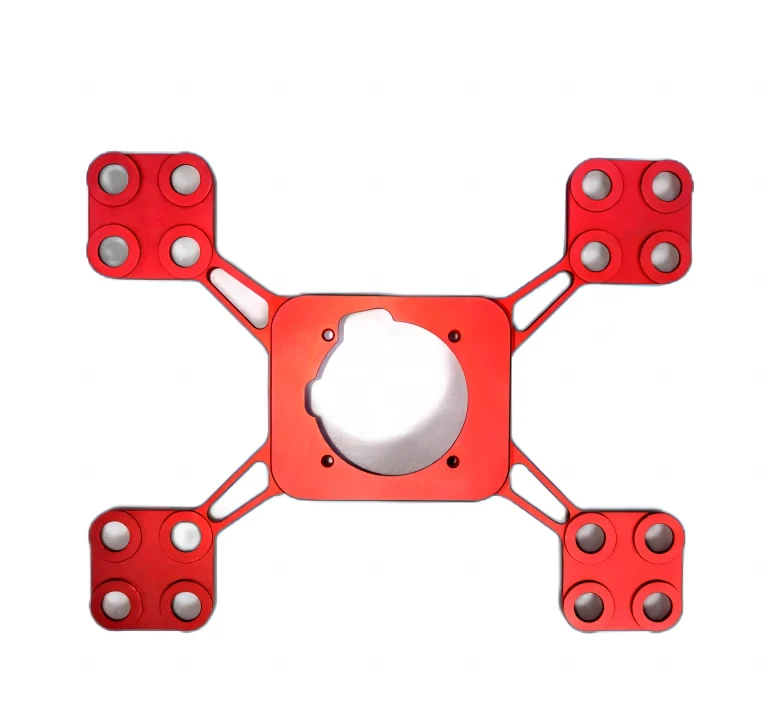

3. Multi-Axis Machining

5-axis CNC machines complete complex parts in one setup, reducing handling time and errors.

4. Real-Time Production Monitoring

IoT-connected systems track progress, allowing operators to make adjustments instantly. This ensures the project stays on schedule.

5. Integrated Logistics Coordination

Some quick-turn CNC machining providers work with dedicated logistics agents. This ensures immediate shipping after production. The right partner can cut delivery delays by 30%.

Data-Driven Performance

-

50% faster lead time compared to traditional machining.

-

Up to 70% reduction in programming time with automated CAM.

-

30% fewer delivery delays when paired with a reliable logistics agent.

-

98% on-time delivery rate for small and large orders alike.

Why You Should Act Now

Quick-turn CNC machining is not just a trend—it’s a necessity for competitive manufacturing. By integrating this method into your supply chain and working with a trusted logistics provider, you can meet deadlines, cut costs, and improve market responsiveness.

Learn more about our precision manufacturing services on our product category page how we achieve industry-leading speed and accuracy.