Drones have revolutionized industries like agriculture, surveillance, and logistics, but their performance depends largely on the quality of their components. Precision UAV components manufacturing play a critical role in maximizing drone efficiency, stability, and durability. In this blog, we’ll explore why precision in manufacturing is key to superior drone performance and how CNC machining offers an advanced solution for crafting these high-quality parts.

The Need for Precision in UAV Components

Unmanned Aerial Vehicles (UAVs), or drones, rely on highly specialized components to function effectively. From propellers and motors to flight controllers and sensors, each part must be crafted with utmost precision. Here’s why precision is indispensable:

1. Enhanced Stability and Control

Drones require precise parts to ensure stable flight and controlled movement. Small discrepancies in manufacturing can lead to imbalanced motors, uneven propeller rotations, and compromised sensors, ultimately affecting the drone’s performance. Precision UAV components help ensure that each part fits seamlessly, leading to smoother and more stable flights.

2. Improved Durability

Precision machining is essential for creating durable drone components that can withstand harsh environments, high-speed operations, and unpredictable conditions. The more accurately parts are made, the less wear and tear the drone will experience over time. This translates to a longer lifespan and reduced maintenance costs.

3. Optimized Efficiency

UAVs are used in critical applications like surveillance and crop monitoring, where efficiency is paramount. Precision components ensure that every part of the drone works at its optimal capacity, improving the overall performance and energy efficiency of the UAV. This means longer flight times and more reliable data collection.

The Role of CNC Machining in Precision UAV Components

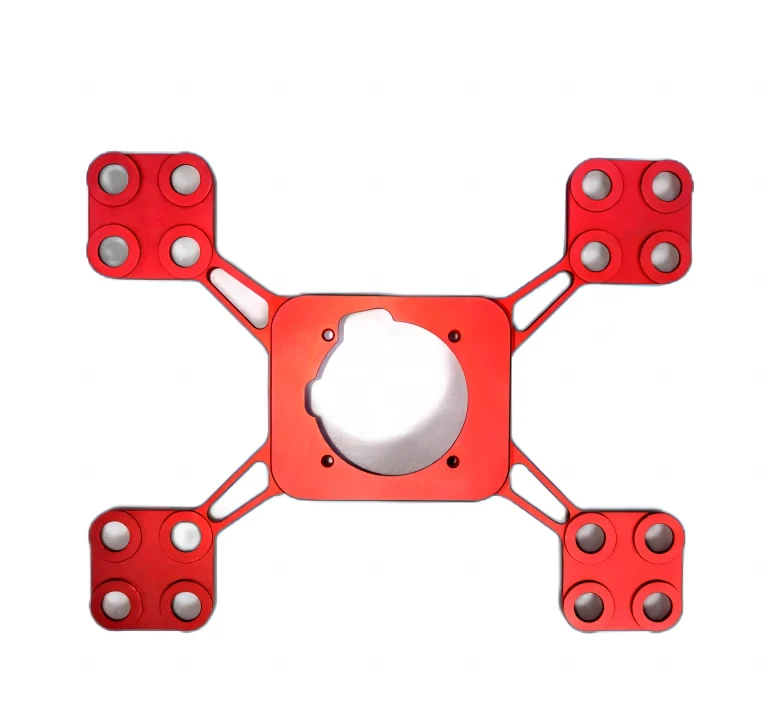

CNC (Computer Numerical Control) machining has emerged as the go-to method for manufacturing precision UAV components. It allows for tight tolerances, high accuracy, and the ability to create complex geometries, making it perfect for the demands of drone manufacturing.

1. High Precision and Tight Tolerances

CNC machining is renowned for its ability to produce parts with precision up to ±0.01mm. This level of accuracy ensures that UAV components fit perfectly, minimizing the risk of operational failure. Whether it’s a flight controller, motor casing, or sensor housing, CNC-machined parts guarantee flawless performance.

2. Complex Geometries for Better Design

The flexibility of CNC machining allows for the production of intricate, custom designs that are crucial for modern UAV applications. With CNC, manufacturers can create lightweight, durable components with intricate details such as cooling vents, optimized mounting points, and more, which are essential for enhancing drone functionality.

3. Consistency and Repeatability

One of the significant advantages of CNC machining is its consistency. After the initial setup, CNC machines can produce identical parts in large volumes without any loss in quality or precision. This is critical for large-scale UAV manufacturers who need consistent and reliable parts for their drones.

The Benefits of Working with Voguc’s CNC Machining Services

When it comes to sourcing high-quality precision UAV components, choosing the right partner is essential. Voguc’s CNC machining services offer industry-leading capabilities in manufacturing custom UAV parts with precision and efficiency.

1. 10 Years of Expertise in CNC Manufacturing

With over a decade of experience in CNC machining, Voguc offers unparalleled expertise in producing high-precision UAV components. Our team understands the complexities of drone designs and delivers parts that meet exact specifications.

2. State-of-the-Art CNC Technology

At Voguc, we use the latest CNC technology, including 3, 4, and 5-axis machines, to produce parts with exceptional accuracy and speed. This technology allows us to handle even the most complex drone components, ensuring they are crafted with precision.

3. Custom Solutions for UAV Manufacturers

We specialize in providing custom CNC machining solutions for UAV manufacturers. Whether you need custom flight controllers, lightweight motor housings, or precision sensors, Voguc can deliver parts that perfectly align with your design requirements.

4. Global Shipping and Timely Delivery

With a focus on reliability, Voguc ensures timely delivery of all CNC-manufactured parts, worldwide. Whether you are in the US, Europe, or Asia, our efficient logistics system guarantees that you receive your UAV components on time, every time.

Conclusion:

The precision of UAV components manufacturing plays a crucial role in ensuring flawless drone performance. Industries rely on drones to perform at their best, which can only happen with high-quality, precisely manufactured parts. With advanced technologies like CNC machining, manufacturers can ensure that their drones deliver superior performance, stability, and durability.

Choosing Voguc’s CNC machining services ensures that your UAV components are crafted with the highest precision, enabling your drones to perform at their best. With over 10 years of experience, cutting-edge technology, and a commitment to quality, Voguc is your trusted partner for precision UAV component manufacturing.

For more information about our CNC machining services, visit our product category to explore how we can help bring your UAV designs to life with unmatched precision.