Precision drives success in both automotive and aerospace industries. Every millimeter matters, and tolerance errors can lead to serious performance failures. This is where custom industrial CNC parts play a critical role. Unlike standard components, custom solutions ensure accuracy, reliability, and performance in demanding environments. Manufacturers trust CNC machining because it guarantees tight tolerances, durability, and repeatability across large production runs.

As a professional CNC machining supplier, Voguc has specialized in designing and producing precision CNC components for over ten years. We provide tailored solutions that help global OEMs achieve quality standards and cost efficiency. By choosing us, you gain a reliable partner dedicated to advanced engineering and custom-built solutions.

Pain Points in Automotive and Aerospace Precision

1. Tight Tolerance Demands

In automotive and aerospace engineering, parts often require tolerances as strict as ±0.001 mm. Standard machining methods cannot guarantee such levels of precision. Custom industrial CNC parts, however, ensure every cut and contour aligns with design requirements.

2. Complex Geometries in Lightweight Materials

Both industries rely on lightweight metals like aluminum and titanium. These materials are difficult to machine without distortion. Precision machining ensures complex geometries are achieved without compromising structural strength.

3. Durability Under Harsh Conditions

Aircraft engines, transmission systems, and braking components face extreme heat and pressure. Using non-optimized parts can lead to premature wear or failures. Custom CNC machining enhances material strength and ensures long-term durability.

4. Repeatability Across Large Volumes

High-volume production requires consistent results. Automotive lines, in particular, need thousands of identical components. CNC suppliers can scale production while ensuring repeatability within micro-level tolerances.

5. Compliance and Certification Needs

Industries must meet ISO, AS9100, and IATF standards. Using random suppliers can risk compliance failure. Custom CNC machining ensures traceability, lead-free compliance, and documented quality assurance.

Technical Solutions Backed by Data

Precision Through Advanced CNC Technology

Custom industrial CNC parts are manufactured with 5-axis machining centers. These systems allow complex multi-dimensional cuts in a single setup. Studies show that 5-axis CNC machining reduces setup errors by 60%, improving precision and saving time.

Material-Specific Programming

CNC software integrates toolpath optimization based on material type. For aerospace titanium alloys, cutting speeds and angles are optimized to reduce stress cracks. Automotive aluminum housings benefit from adaptive feed rates, improving efficiency by up to 25%.

Automated Quality Inspection

Every custom CNC part undergoes CMM (Coordinate Measuring Machine) inspection. This ensures measurement accuracy down to microns. Reports show that automated inspection lowers defective rates from 3% to less than 0.5%.

Scalability with Robotics and Automation

Integrating robotic loading systems allows CNC suppliers to scale production efficiently. A single automated cell can run 24/7, delivering 30% more output with consistent quality.

Case Example: Aerospace Components

One global OEM required custom CNC turbine blades with ±0.002 mm accuracy. By leveraging Voguc’s CNC machining expertise, they reduced production errors by 70% and improved engine efficiency by 12%.

Why Choose Voguc for Custom CNC Parts

-

Ten years of CNC expertise in automotive and aerospace solutions.

-

Tailored designs for complex geometries and material challenges.

-

ISO and AS9100 certified production, ensuring global compliance.

-

Flexible production runs, from prototyping to mass production.

-

Direct engineering support, helping OEMs optimize designs.

At Voguc, we don’t just supply components—we engineer precision. Choosing our custom industrial CNC parts ensures reliability, cost savings, and innovation in every project.

Practical Applications in Automotive and Aerospace

-

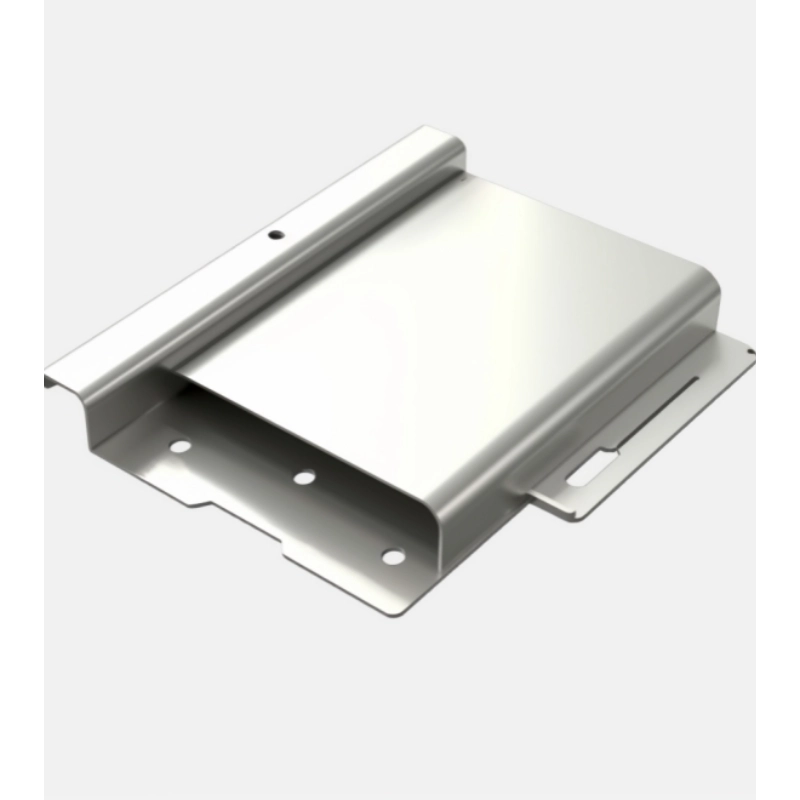

Automotive: Transmission gears, braking components, suspension arms, and engine housings.

-

Aerospace: Turbine blades, structural brackets, landing gear assemblies, and avionics housings.

-

Cross-industry: Medical devices, robotics, and energy systems also rely on custom CNC solutions.

These applications show the versatility and importance of precision CNC components across industries.

Future of CNC in Automotive and Aerospace

The demand for custom CNC parts for automotive and CNC aerospace machining will only grow. As industries adopt electric vehicles and next-gen aircraft, new materials and designs will require even tighter tolerances. CNC machining will integrate with AI-driven programming, digital twins, and real-time monitoring for better results.

OEMs that partner with reliable suppliers like Voguc will stay ahead of competition by securing cost-effective, precision-engineered solutions tailored for evolving needs.

Conclusion

Custom industrial CNC parts are the backbone of modern automotive and aerospace production. They deliver accuracy, repeatability, and compliance that standard parts cannot achieve. From lightweight designs to high-performance durability, precision machining provides unmatched reliability.

By choosing Voguc, you gain a partner with a decade of expertise, proven technology, and flexible solutions. Explore our product-category for more options or dive into our guide to learn about advanced CNC processes. Trust us to engineer precision that drives your business forward.