In today’s fast-paced industrial world, high-volume CNC contract manufacturing has become the backbone of efficient, scalable, and cost-effective production. Whether you operate in automotive, aerospace, medical devices, or electronics, selecting the right overseas CNC partner determines your product quality, delivery reliability, and long-term competitiveness.

Outsourcing CNC machining overseas offers advantages like reduced costs, flexible scaling, and access to advanced machining capabilities. However, finding a reliable CNC manufacturer requires careful evaluation of technical expertise, production capacity, and quality systems. This guide will help you identify what to look for — and why choosing Voguc CNC services can make a difference.

Key Factors to Consider When Choosing a High-Volume CNC Contract Manufacturing Partner

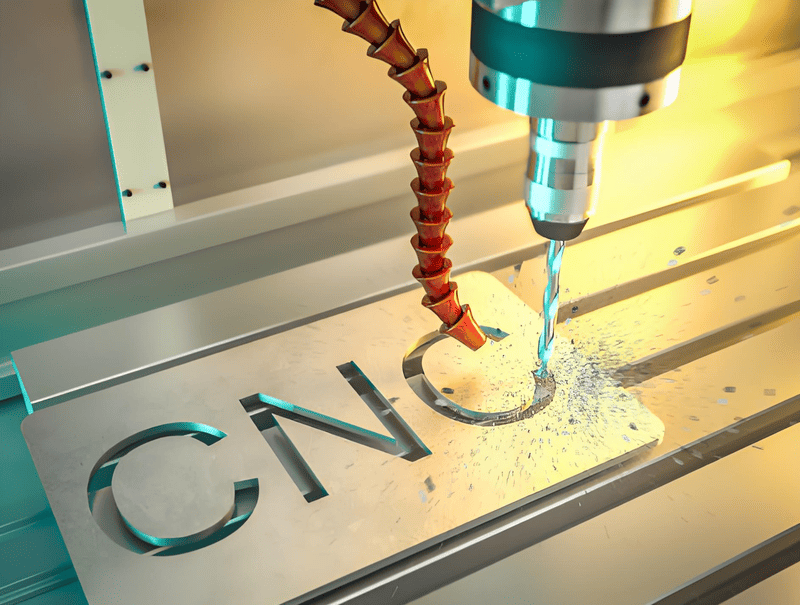

1. Evaluate Technical Expertise and Equipment Capability

Your manufacturing partner should demonstrate strong technical skills, modern equipment, and multi-axis machining capability. Look for:

-

5-axis CNC machining for complex geometries

-

Automated production lines for consistent results

-

Precision tolerance control (±0.005mm or better)

-

Material versatility — aluminum, stainless steel, titanium, and engineering plastics

These ensure your high-volume CNC contract manufacturing runs efficiently while meeting the strict standards of automotive, medical, and aerospace sectors.

2. Verify Quality Management and Certifications

A trustworthy CNC partner must follow international quality standards. Always confirm that they have:

-

ISO 9001:2015 certification for quality consistency

-

RoHS compliance for environmentally safe materials

-

PPAP and FAI documentation for traceable production

-

Regular CMM inspection reports for precision assurance

At Voguc CNC, our quality process integrates 100% dimensional inspection, surface roughness testing, and material traceability, guaranteeing every batch meets customer requirements.

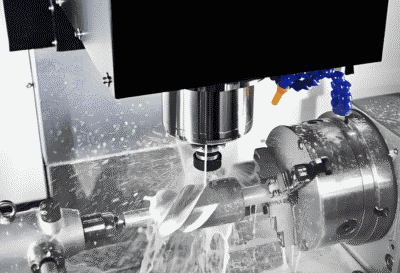

3. Assess Supply Chain and Production Capacity

For high-volume CNC production, scalability is critical. Evaluate how your supplier handles bulk orders, component variation, and logistics. A strong manufacturer should provide:

-

Flexible production scheduling to meet deadlines

-

Inventory management for continuous supply

-

Global shipping and packaging support

-

Transparent lead-time reporting

Ensuring Communication and Project Transparency

1. Choose Partners with Responsive Communication

Effective communication bridges cultural and time zone differences. A professional CNC manufacturer should provide:

-

Dedicated project managers for each order

-

Real-time progress updates and production photos

-

Quick responses to design or tolerance adjustments

Transparent communication builds trust — a key factor when managing overseas manufacturing.

2. Review Their Engineering Support and DFM Capabilities

Beyond machining, a qualified CNC partner offers Design for Manufacturability (DFM) support. This ensures parts are optimized for cost, strength, and efficiency before mass production.

At Voguc CNC, our engineers assist from prototype to high-volume production, ensuring part performance and reducing rework time. This technical partnership saves both cost and lead time.

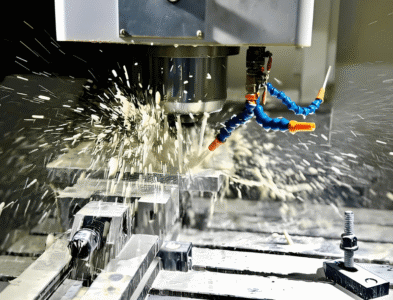

Sustainability and Cost Efficiency in CNC Manufacturing

As global industries focus on green manufacturing, sustainability now defines the best CNC partnerships. When choosing a supplier, consider:

-

Use of recyclable materials (aluminum, brass, stainless steel)

-

Energy-efficient machining processes

-

Waste recycling and coolant recovery systems

-

Commitment to reducing carbon footprint

Choosing a sustainable high-volume CNC contract manufacturer like Voguc CNC supports not only environmental goals but also long-term cost control and corporate responsibility.

Why Choose Voguc CNC Services for High-Volume Contract Manufacturing

1. Proven Experience in Multi-Industry Projects

Voguc CNC has served clients across automotive, aerospace, medical, and electronics for decades. Our precision manufacturing has powered complex global supply chains and OEM product launches.

2. Advanced Machining and Inspection Technology

Voguc has several specialized CNC machines, including 5-axis vertical machining machines, which ensure consistent precision at scale. Each batch undergoes automated measurement, ensuring tolerances as tight as ±0.005mm.

3. End-to-End Manufacturing Solutions

From prototype development to bulk shipment, Voguc CNC provides integrated services:

-

Rapid prototyping

-

Precision machining

-

Surface finishing (anodizing, polishing, sandblasting)

-

Assembly and packaging

-

Global logistics coordination

This end-to-end solution simplifies international outsourcing and guarantees reliable supply continuity.

Conclusion:

Finding a dependable high-volume CNC contract manufacturing partner overseas goes beyond price comparison. It’s about reliability, communication, and shared quality goals. By partnering with a manufacturer like Voguc CNC, you gain technical excellence, scalable production, and sustainable manufacturing solutions — all essential for modern OEM and B2B success.

FAQs

Q1: What industries benefit most from high-volume CNC contract manufacturing?

A1: Industries like automotive, aerospace, medical devices, and electronics benefit from the precision, scalability, and consistency offered by high-volume CNC machining.

Q2: How can I ensure quality when outsourcing CNC machining overseas?

A2: Look for certified manufacturers with ISO 9001:2015, robust inspection systems, and transparent reporting. Partnering with experienced firms like Voguc CNC ensures quality control.

Q3: What makes Voguc CNC a reliable long-term manufacturing partner?

A3: Voguc CNC combines advanced technology, engineering expertise, and global logistics capability to deliver precision components efficiently and sustainably.