In the medical equipment industry, precision and reliability are non-negotiable. Every component must perform flawlessly under extreme conditions, where even a slight imperfection can affect patient safety. This is where Custom CNC ground components play a crucial role. With tight tolerances and mirror-smooth finishes, they significantly improve the durability, accuracy, and longevity of critical medical devices.

Partnering with a trusted manufacturer like Voguc, known for precision CNC machining excellence, ensures every part meets strict ISO and RoHS standards, supporting both performance and regulatory compliance.

What Are Custom CNC Ground Components?

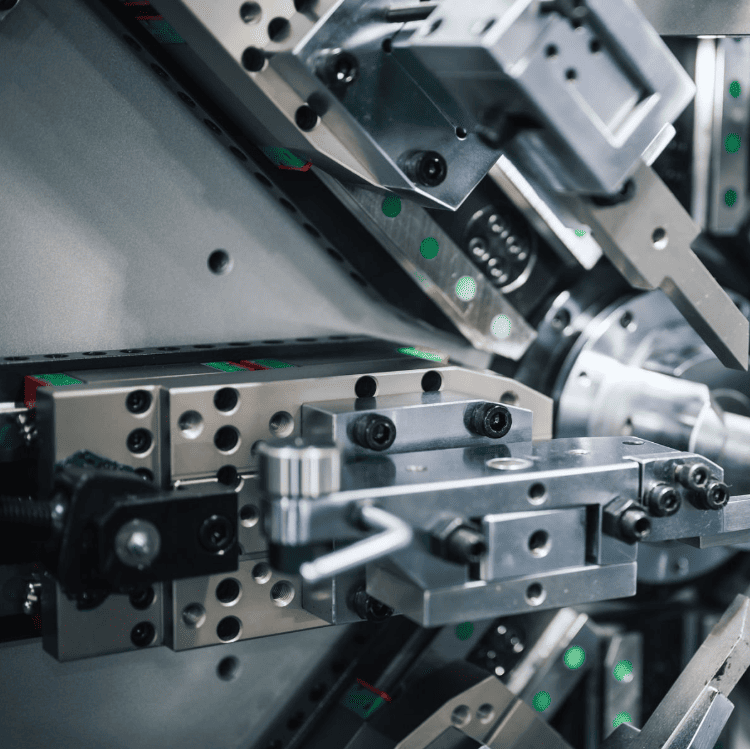

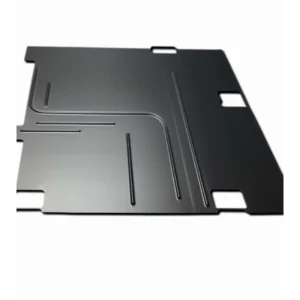

CNC ground components are precision-engineered parts that undergo CNC machining followed by surface grinding to achieve ultra-flat, dimensionally accurate finishes.

In medical applications, these components are used in devices such as:

-

Surgical instruments

-

Diagnostic scanners

-

Prosthetic assemblies

-

Implantable support structures

These parts are manufactured from durable materials like stainless steel, titanium, and aluminum, all chosen for their biocompatibility and corrosion resistance.

Why Durability Matters in Medical Equipment

Durability in medical equipment directly impacts device performance, patient safety, and maintenance costs. Hospitals and medical laboratories rely on machines that can function accurately for years. Any wear or misalignment could lead to diagnostic errors or surgical risks.

High-quality Custom CNC ground components ensure:

-

Precision fits between mechanical interfaces

-

Minimal friction and wear under repeated sterilization cycles

-

Resistance to corrosion and contamination

-

Stable operation over time

These features collectively extend the service life of medical equipment and reduce downtime.

How CNC Grinding Enhances Component Strength

The grinding process refines a component’s surface at the micron level, removing microscopic irregularities. This improves both tolerance accuracy and mechanical strength.

Key Benefits of CNC Grinding for Medical Parts

-

Enhanced Surface Integrity: Eliminates micro-cracks, improving fatigue resistance.

-

Dimensional Precision: Achieves tolerances as tight as ±0.001 mm.

-

Improved Material Density: Grinding strengthens metal grain structures.

-

Superior Aesthetic Finish: Ideal for visible or high-contact components.

For example, surgical instrument hinges and pump shafts require exact alignment and smooth motion — both achievable through CNC-ground finishing.

Material Selection: The Foundation of Longevity

Different medical components require specific material properties. Voguc engineers carefully select materials based on each device’s function and regulatory requirements.

| Material | Key Properties | Typical Applications |

|---|---|---|

| Stainless Steel 316L | Corrosion-resistant, biocompatible | Surgical tools, dental parts |

| Titanium Alloy | Lightweight, strong, non-reactive | Implants, prosthetic joints |

| Aluminum 6061-T6 | High machinability, thermal stability | Diagnostic housings, connectors |

By combining precision CNC machining with surface grinding, these materials achieve optimal durability and long-term stability.

Precision Standards in Medical CNC Machining

The medical industry demands unmatched precision. Custom CNC ground components must meet international standards, including:

-

ISO 9001:2015 — Quality management

-

ISO 13485:2016 — Medical device manufacturing

-

RoHS & REACH compliance — Safe, lead-free materials

Voguc ensures every part undergoes:

-

Dimensional inspections using coordinate measuring machines (CMM)

-

Surface roughness testing for smoothness validation

-

Full traceability through material certificates

This attention to detail helps clients maintain compliance with FDA and CE requirements, a key advantage for global medical device exporters.

How Voguc Ensures Consistency and Quality

As a professional Custom CNC ground components manufacturer, Voguc applies a three-stage quality assurance process:

-

Design Review & Prototyping – Engineers analyze CAD drawings for manufacturability.

-

Precision Machining & Grinding – Automated 5-axis CNC centers achieve sub-micron accuracy.

-

Final Inspection & Packaging – Every part is tested under cleanroom-like conditions before delivery.

This rigorous approach ensures each medical component is consistent, reliable, and compliant.

Environmental & Cost Advantages

Besides precision, CNC ground components also contribute to eco-friendly manufacturing.

-

Reduced material waste: Advanced machining algorithms optimize cutting paths.

-

Lower energy consumption: Automated equipment minimizes idle time.

-

Extended equipment life: Fewer replacements reduce carbon footprint.

By choosing Voguc, you not only improve equipment performance but also support sustainable production practices.

Conclusion

In the rapidly evolving field of medical technology, the reliability of your equipment depends on the precision of its components. Custom CNC ground components ensure exceptional durability, long-term accuracy, and compliance with international medical standards.

Partnering with Voguc gives manufacturers access to advanced grinding technologies, premium materials, and strict quality controls — ensuring your medical equipment performs at its best, year after year.

FAQs

1. Why are CNC ground components important for medical equipment?

Because they enhance accuracy, reduce friction, and ensure long-term performance under sterilization and heavy use.

2. What tolerances can Voguc achieve in medical CNC components?

Voguc can achieve ultra-precision tolerances up to ±0.001 mm, ideal for high-accuracy medical applications.

3. Are Voguc’s CNC ground components compliant with medical standards?

Yes. All parts meet ISO 13485 and RoHS standards, ensuring full regulatory compliance for international markets.