In the manufacturing world, precision is paramount. From aerospace components to medical devices, the need for high-precision parts is ever-growing. CNC machining for high-precision parts offers unparalleled accuracy and reliability, making it the preferred choice for many industries.

With its ability to create complex shapes and tolerances with minimal human intervention, CNC machining has become a cornerstone of modern manufacturing. In this article, we’ll explore the key benefits of CNC machining for high-precision parts manufacturing and why it’s a game-changer for industries that demand exacting standards.

What Is CNC Machining for High-Precision Parts?

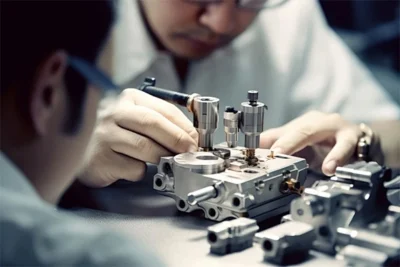

CNC machining (Computer Numerical Control) is a manufacturing process that uses computer-controlled machines to perform a variety of tasks such as cutting, drilling, milling, and turning. For high-precision parts, CNC machines work with incredibly fine tolerances, producing parts that meet the most stringent specifications.

Unlike traditional machining methods, CNC machines automate the production process, offering precision, consistency, and repeatability. This automation reduces the chance of human error and ensures the production of parts that are identical to each other, even in large quantities.

Key Benefits of CNC Machining for High-Precision Parts

1. Exceptional Accuracy and Tolerances

One of the most significant advantages of CNC machining for high-precision parts is its ability to deliver extraordinary accuracy. CNC machines follow a digital blueprint, which ensures that each part is manufactured according to the precise specifications, without deviation.

-

Tight Tolerances: CNC machines can produce parts with tolerances as tight as 0.001 inches (25 microns), which is critical for industries such as aerospace, automotive, and medical device manufacturing.

-

Consistent Quality: Once a part design is programmed, CNC machines consistently produce identical parts, ensuring uniformity throughout the production process.

For industries that require exact specifications, CNC machining is the most reliable solution.

2. Flexibility in Design and Complexity

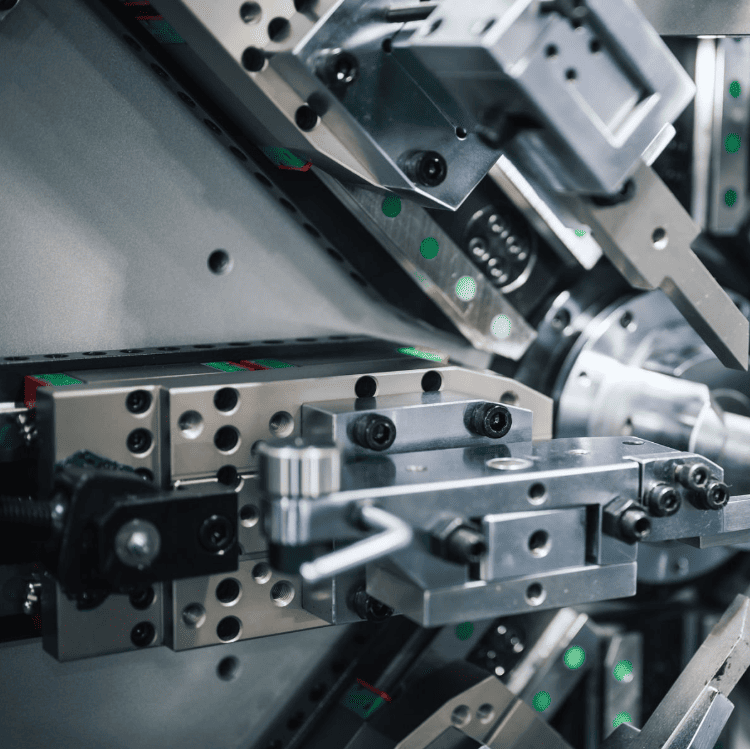

CNC machining for high-precision parts offers exceptional flexibility in design. It can create parts with complex geometries, intricate details, and fine features that would be difficult or impossible to achieve with traditional manufacturing methods.

-

Complex Geometries: CNC machines excel at producing parts with curves, angles, and intricate features that require high levels of precision.

-

Rapid Prototyping: CNC machining allows manufacturers to quickly develop prototypes and make adjustments, speeding up the design-to-production process.

This flexibility enables manufacturers to create custom parts tailored to specific applications, whether for a limited run or mass production.

3. Enhanced Efficiency and Reduced Lead Times

CNC machining for high-precision parts streamlines production, reducing the time needed to manufacture complex parts. Once a part design is loaded into the machine, it can run autonomously, producing multiple parts simultaneously.

-

Faster Production: CNC machines operate faster than traditional machining methods, especially for complex parts that require multiple operations.

-

Reduced Human Error: Since the process is automated, there’s less chance for human error, which can slow down production or require costly rework.

The efficiency of CNC machining makes it ideal for industries with demanding production schedules, ensuring fast delivery without sacrificing quality.

4. Material Flexibility and Strength

CNC machining can work with a wide variety of materials, including metals (like steel, aluminum, titanium), plastics, and composites. This makes it ideal for creating high-precision parts in industries like aerospace, automotive, and medical.

-

Versatile Materials: CNC machining allows manufacturers to choose the best material for each part based on its specific requirements, whether strength, heat resistance, or electrical conductivity is needed.

-

Stronger Parts: The precision of CNC machining ensures that parts are made to the exact specifications, resulting in stronger, more durable components.

Whether you need lightweight parts or components that must withstand extreme conditions, CNC machining offers the material versatility required for high-precision manufacturing.

5. Cost-Effective for Low to High-Volume Production

While CNC machining for high-precision parts may have higher initial setup costs compared to traditional methods, it becomes cost-effective, especially for low to medium-volume production runs.

-

Lower Labor Costs: With automation in place, fewer operators are required to oversee production, reducing overall labor costs.

-

Efficient Material Use: CNC machines minimize material waste by cutting parts with high precision, ensuring that no materials are wasted unnecessarily.

Whether you’re producing one prototype or thousands of parts, CNC machining offers an economically viable solution that optimizes both time and cost.

Conclusion:

CNC machining for high-precision parts provides manufacturers with a reliable, efficient, and cost-effective solution to produce high-quality components. Its ability to deliver tight tolerances, work with complex designs, and use a variety of materials makes it indispensable in industries where precision is non-negotiable.

At Voguc, we specialize in offering CNC machining solutions that deliver precision, efficiency, and flexibility. Our expert team ensures that every part meets your exact specifications, making us the ideal partner for your manufacturing needs.

Frequently Asked Questions

1. What types of materials can be used in CNC machining for high-precision parts?

CNC machining can work with a variety of materials, including metals (steel, aluminum, titanium), plastics, and composites. The material choice depends on the part’s specific requirements, such as strength, heat resistance, and durability.

2. How does CNC machining ensure high accuracy?

CNC machines follow pre-programmed designs with extreme precision, allowing for tight tolerances and repeatable accuracy. Automated processes reduce the risk of human error and ensure consistent results.

3. Is CNC machining cost-effective for low-volume production?

Yes, CNC machining is cost-effective for both low and high-volume production. It reduces labor costs and material waste, making it ideal for both small batches and large production runs.