Small-batch production is rising fast in today’s automotive world. Brands move quicker. Models change often. Drivers also ask for custom parts. Because of this shift, manufacturers need flexible and precise methods. Automotive CNC machining services now play a critical role.

This process offers accuracy, flexibility, and repeatability. It also cuts waste and reduces risk in prototyping. As low-volume demand grows, CNC machining becomes the smartest choice. In this article, you will learn why CNC machining stands out. You will also discover how partners like Voguc help teams reach higher production standards.

Understanding the Needs of Small-Batch Automotive Production

Small-batch production supports quick development cycles. Automakers use it for prototypes, custom trims, and aftermarket upgrades. Yet, this type of production also creates challenges.

Main Challenges in Low-Volume Automotive Manufacturing

Manufacturers often face:

-

High tooling costs

-

Long lead times

-

Strict quality needs

-

Frequent design changes

-

Reduced tolerance for errors

Because these limits can slow teams down, many turn to CNC machining. It solves most of the issues that low-volume car component production brings.

Key Advantages of Automotive CNC Machining in Small-Batch Production

CNC machining offers a group of clear benefits. These advantages support speed, quality, and design freedom. Let’s explore the major ones.

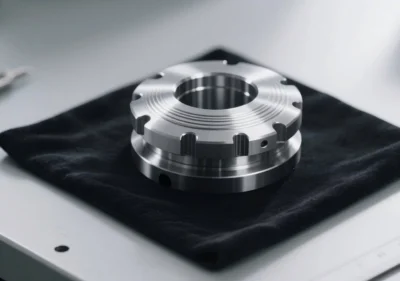

1. High Precision for Complex Car Components

CNC machining delivers micro-level accuracy. This is important when producing:

-

Engine brackets

-

Brake system parts

-

Transmission components

-

Sensor housings

-

Steering system parts

Every cut remains consistent from part to part. Even in small batches, quality never drops. Teams can reach tight tolerances with ease. This precision keeps safety and performance high.

2. Fast Turnaround Time for Prototyping

Speed matters during development. CNC machining reduces delays because:

-

There is no need for complex tooling

-

Engineers can adjust designs quickly

-

Machining starts as soon as files upload

As a result, teams iterate faster. Designers also test more variations in less time. This makes CNC machining ideal for concept-stage and validation-stage projects.

3. Cost-Effective for Low-Volume Production

Traditional methods require expensive molds. That cost makes small batches difficult. However, CNC machining avoids these issues. It cuts cost because:

-

No molds are required

-

Setup time is short

-

Waste stays low

-

Revision costs remain small

Because of this, CNC machining becomes the most cost-effective option under 200–500 pieces.

4. Wide Material Compatibility

Automotive CNC machining supports metal and plastic materials. Common materials include:

-

Aluminum

-

Stainless steel

-

Brass

-

PEEK

-

ABS

-

Nylon

-

Carbon fiber composites

This flexibility helps engineers match exact performance requirements. For example, stainless steel suits high-strength needs. Meanwhile, aluminum supports lightweight design goals. CNC machining handles both with ease.

5. Improved Design Flexibility

Design teams gain freedom with CNC machining. They can:

-

Test new structures

-

Modify dimensions

-

Explore custom shapes

-

Produce functional parts without compromise

Because no molds lock the design, engineers change details anytime. This creates a smoother path from design to testing.

6. Strong Repeatability for High-Quality Results

CNC machining runs on digital programming. So, every part produced stays consistent. In small batches, maintaining repeatability is vital. Car components cannot vary. CNC machining ensures each piece meets the same standard.

7. Enhanced Durability and Performance in Car Parts

Because CNC machining uses solid blocks of material, final components stay strong. They also perform well in harsh automotive conditions. CNC-machined pieces resist:

-

Heat

-

Vibration

-

Corrosion

-

Friction

This gives manufacturers confidence when parts must endure real-world stress.

Why Many Automotive Brands Choose Us — Voguc

At Voguc, we support global automotive teams with top-level automotive CNC machining services. Our service helps projects move faster, safer, and smoother. Many clients choose us because:

-

We hold advanced CNC equipment

-

We support metal and plastic machining

-

We deliver quick lead times

-

We accept prototypes and small batches

-

We follow strict quality control standards

Because we value precision and long-term results, our work helps brands stay ahead.

Applications of CNC Machining in Small-Batch Car Component Production

CNC machining supports many fields in the automotive world. Below are common applications.

Prototyping for New Vehicle Models

Teams test structural and functional parts early. CNC machining gives real results that help them adjust quickly.

Customized Aftermarket Car Parts

Car owners often want unique parts. CNC machining supports small-batch custom upgrades for them.

Low-Volume OEM Replacement Parts

Some models require parts that are no longer mass produced. CNC machining fills that gap without high cost.

Validation and Material Testing

Engineers review material strength, heat performance, and dimensional accuracy using CNC-machined parts.

Conclusion

Automotive CNC machining gives small-batch producers a powerful advantage. It improves accuracy, speeds up testing, cuts costs, and also supports flexible design. When teams need reliable, low-volume production, CNC machining stands above all other methods.

If you want stable results and strong performance, consider Voguc. Our automotive CNC machining services help brands reach top-level quality with speed and confidence.

FAQs

1. Can CNC machining handle both plastic and metal car parts?

Yes. CNC machining supports aluminum, steel, brass, ABS, nylon, and more.

2. Is CNC machining suitable for prototype testing?

Yes. It provides fast turnaround and high precision, ideal for early testing stages.

3. How many parts qualify as small-batch production?

Most automotive teams treat 10–500 pieces as a small batch, and CNC machining works well for that range.