As Black Friday approaches, businesses are gearing up for big savings, and if you’re in the manufacturing or construction industry, there’s never been a better time to take advantage of exclusive offers on sheet metal fabrication processes. Whether you need precision custom parts or high-volume production runs, understanding the best sheet metal fabrication processes and how to select the right one for your project can lead to both savings and enhanced efficiency. In this blog, we’ll explore the top fabrication processes, how to make the most of Black Friday deals, and why choosing a reliable partner like Voguc could elevate your business operations!

Why Choose the Best Sheet Metal Fabrication Processes?

When it comes to manufacturing, sheet metal fabrication processes are fundamental in creating durable, precise, and cost-effective products. The right fabrication process can significantly impact the quality, timeline, and cost of your project. Let’s break down the advantages of using the best processes:

-

Precision and Quality: Using high-quality materials and processes ensures accuracy in product dimensions, which is essential for industries such as aerospace, automotive, and electronics.

-

Cost Efficiency: Selecting the appropriate fabrication method helps in minimizing waste and reducing production costs.

-

Flexibility: Different fabrication processes offer varied options in terms of design flexibility, material choices, and scalability for custom orders.

Top Sheet Metal Fabrication Processes to Consider

When choosing a sheet metal fabrication process, it’s important to know which techniques best suit your needs. Here are some of the most popular processes:

1. Laser Cutting

Laser cutting uses a high-powered laser to cut through sheet metal with precision. It’s ideal for intricate designs and high-accuracy applications, such as electronics enclosures and custom panels.

-

Advantages: High precision, smooth edge quality, fast production speed, and the ability to cut complex shapes.

-

Best For: Custom designs, prototype runs, and high-precision applications.

2. CNC Punching

CNC punching involves using a punching machine controlled by a computer to create holes in the sheet metal. It is often used for creating a large number of holes in a sheet metal part, typically for industrial applications.

-

Advantages: High-speed processing, consistent hole patterns, and efficient for mass production.

-

Best For: Parts with repeated patterns of holes or cutouts, such as brackets and panels.

3. Metal Stamping

Metal stamping is a process that involves pressing a die onto the metal sheet to shape it. This process is perfect for producing high volumes of parts that require uniformity and strength.

-

Advantages: High-speed production, cost-efficient for large quantities, and strong, durable parts.

-

Best For: High-volume parts such as automotive components, appliances, and electronics.

4. Welding and Joining

Welding and joining techniques are critical for assembling parts and structures in sheet metal fabrication. Involves melting the metal at the joint, while joining techniques might include riveting or gluing.

-

Advantages: Strong, durable joints and flexibility in joining different materials.

-

Best For: Creating large structures, assemblies, and complex geometries.

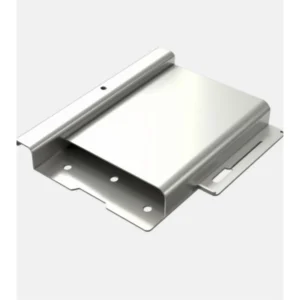

5. Bending and Forming

Bending is a process used to shape the metal by applying force to create an angle or curve. It’s particularly useful for parts that require specific angles for assembly.

-

Advantages: Flexible and versatile, allows for a range of angles and shapes.

-

Best For: Structural components, brackets, and frames.

Maximizing Your Savings with Black Friday Deals

This Black Friday, you can enjoy exclusive discounts on custom sheet metal fabrication orders from Voguc, your trusted partner in the industry. Whether you’re looking for one-time custom parts or planning a long-term manufacturing project, now is the perfect time to save. Take advantage of these discounts to maximize your budget and get high-quality products at a fraction of the cost.

How to Choose the Right Sheet Metal Fabrication Process for Your Needs

Selecting the best fabrication process depends on several factors, including:

-

Material Type: Different processes work better with certain materials, such as steel, aluminum, or copper.

-

Production Volume: For small batches, laser cutting or CNC punching may be more cost-effective, while metal stamping is better for high-volume production.

-

Tolerance and Precision: For projects that require high accuracy, laser cutting and CNC machining may be the best options.

-

Lead Time: If you need quick turnaround, processes like laser cutting or CNC punching tend to be faster.

Key Considerations When Selecting a Fabrication Partner:

-

Experience and Reputation: Choose a manufacturer with a proven track record of delivering high-quality results.

-

Customization Options: Make sure the fabricator can handle your specific requirements and provide tailored solutions.

-

Customer Support: Reliable communication and after-sales support can save you time and money in the long run.

Conclusion:

When it comes to custom sheet metal fabrication, our team combines expertise, precision, and advanced technology to deliver top-tier products that meet your exact specifications. Plus, with our Black Friday discounts, you can access high-quality fabrication services at unbeatable prices.

Choose Voguc for your next project and take advantage of our special offers today!

FAQs:

1. What is the most cost-effective sheet metal fabrication process for small projects?

Laser cutting and CNC punching are often the most cost-effective options for small projects due to their precision and quick setup.

2. How can I ensure my custom metal parts meet my specifications?

Work closely with a reputable manufacturer, like Voguc, to ensure that your design is properly reviewed, and all specifications are clearly communicated.

3. Are there any additional services that can complement my sheet metal fabrication needs?

Yes, services like welding, powder coating, and assembly can be added to your order, helping to streamline the process and reduce costs.