Do your metal parts arrive with jagged edges or wrong dimensions? 📉 Many engineers face inconsistent quality from their fabrication partners today. Low-quality components lead to expensive assembly delays and failures now. Specifically, weak welds and poor finishes can ruin your reputation. You need a custom sheet metal parts supplier that values perfection. Finding a reliable manufacturing partner is finally possible for your business. Stop settling for “good enough” in your industrial supply chain. Discover the critical standards that define a truly elite fabricator. 🚀 Your journey to high-precision hardware starts right here. Let us explore the world of industrial quality together.

The Science of Precision in Metal Fabrication 📐

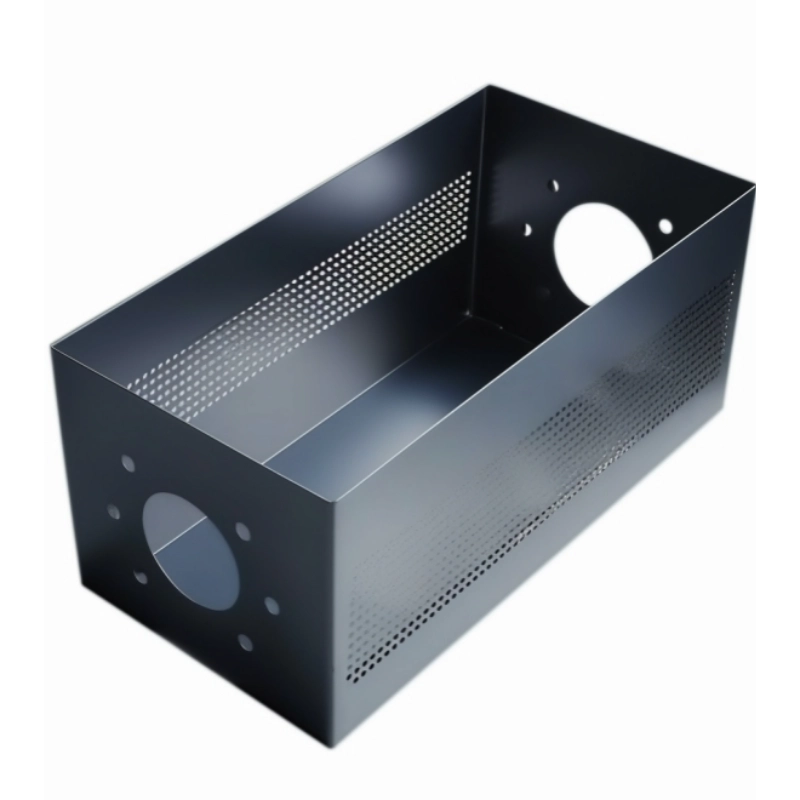

A top custom sheet metal parts supplier follows strict protocols. They do not just cut metal; they engineer solutions. Specifically, 2026 standards require advanced CNC machinery for every single cut. This technology ensures your parts match your CAD files perfectly. Furthermore, high-quality material sourcing is the foundation of any project. You must verify that your supplier uses certified metal alloys. This prevents rust and structural weakness in your final products. 💡 Modern shops also provide DFM (Design for Manufacturing) feedback immediately. This helps you catch design errors before production starts. Consequently, you save time and reduce wasted material costs. Every millimeter matters when you are building professional-grade hardware.

The Importance of ISO 9001 Certification 🛡️

Why should you check for ISO certifications before ordering? A certified custom sheet metal parts supplier follows global management rules. They document every step of the fabrication process for you. This creates a clear trail of accountability for your parts. Moreover, it ensures consistent quality over thousands of units produced. You get the same precision in every single batch. Therefore, certification is a non-negotiable standard for serious buyers.

Advanced Surface Finishing and Inspection Standards ✨

Quality does not stop once the metal is cut. Your custom sheet metal parts supplier must offer professional finishes. Specifically, powder coating and anodizing protect parts from harsh environments. Modern shops use automated inspection tools like CMM machines now. These tools verify tolerances down to a few microns easily. Consequently, you receive parts that fit your assembly every time. Accuracy is the hallmark of a world-class manufacturing partner.

Achieve Production Excellence with a Reliable Partner 🏆

Imagine launching your product with total confidence in every part. 🌟 Your assembly line moves smoothly without any fitting issues. Using an elite custom sheet metal parts supplier makes this real. You no longer worry about late shipments or defective goods. ✨ Instead, you focus on growing your brand and innovation. Experience the professional pride of using perfectly crafted metal components. 🌟 Your clients will notice the superior build quality of your machines. Choose Voguc to master your complex metal fabrication needs. Better parts lead to more durable and successful hardware products. High-quality manufacturing turns your designs into a competitive market advantage. You deserve a partner that cares about your engineering goals.

Why Leading Engineering Teams Choose Our Standards? 📈

Reliable manufacturing is the backbone of any successful hardware company. See why our quality standards lead the metal industry:

-

DFM Expertise: We optimize your designs for the most efficient production.

-

Rapid Prototyping: Get your samples in days, not weeks or months.

-

Material Traceability: We provide full mill reports for every metal sheet.

-

Scalable Production: Move from one prototype to mass production effortlessly.

-

Strict QC: Every part undergoes a multi-point manual and digital check.

Success Story: From Prototype to Global Market 🏢

One robotics startup struggled with poor part tolerances last year. They switched to our custom sheet metal parts supplier services. We identified three design flaws in their initial CAD files. By fixing these, we reduced their assembly time by 30%. Their robots are now more stable and much more durable. Specifically, their production costs dropped due to fewer rejected parts. They successfully secured their next round of funding last month.

Secure Your High-Precision Metal Parts Today 🛒

The demand for high-quality hardware is growing faster than ever. Do not let a mediocre supplier slow your company down. Explore the best custom sheet metal parts supplier solutions online. Choose Voguc to receive a free professional DFM audit. 📦 Our team will review your drawings and provide expert feedback. We offer flexible options for laser cutting, bending, and welding. Improve your product quality and lower your manufacturing risk today. 🛒 Take the first step toward industrial excellence right now. Contact our specialized fabrication team for a personalized project quote.

Ready to Elevate Your Metal Component Quality? ✅

-

Upload your CAD files to our secure online portal.

-

Select the exact material and finish for your project.

-

Choose the Voguc to access our high-speed laser technology.

-

Review our detailed quote and production timeline for your parts.

-

Start your first production run and experience true precision.

Visit our official site to browse our latest fabrication gallery. Read testimonials from engineers who trust our precision-driven systems. Find the perfect balance between competitive pricing and elite quality. The future of your hardware depends on the best parts. Contact us today to secure your manufacturing success! 🖱️✨

Quality is Your Most Valuable Asset 🏁

In 2026, precision is the key to winning in hardware. A great custom sheet metal parts supplier acts as an extension of your team. They protect your designs and ensure your brand’s long-term success. Make your production as sharp and reliable as your vision. Your global success begins with a perfectly fabricated metal part. 🥂

Frequently Asked Questions

1. What tolerances can a top supplier maintain?

Most elite suppliers maintain tolerances within +/- 0.1mm for standard parts. For high-precision projects, we can reach even tighter limits using CNC. Choose the Voguc for projects that require extreme dimensional accuracy. 📏

2. How do you ensure the metal won’t rust?

We offer various surface treatments like galvanizing or specialized powder coating. We also verify the grade of stainless steel through chemical testing. This ensures your parts survive in outdoor or humid environments easily. 🌦️

3. Can you help with low-volume custom orders?

Yes, a flexible custom sheet metal parts supplier handles small batches. We support your prototyping phase before you move to mass production. This allows you to test your market without a huge investment. 🛠️