CNC machining for car parts has revolutionized modern automotive manufacturing. With faster production and tighter tolerances, this technology ensures durability and efficiency. Many industries demand not only speed but also lead-free compliance and eco-friendly methods. Today, CNC machining for car parts is a core solution for custom designs, high-strength components, and scalable production.

In this guide, we’ll explore common pain points, demonstrate how CNC machining solves them, and explain why Voguc CNC machining services is the partner you can trust.

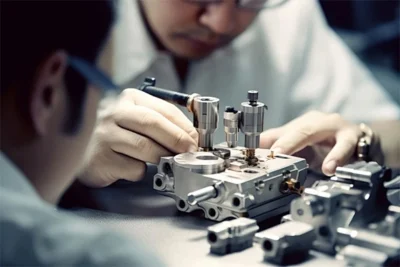

Precision in Automotive Parts Manufacturing

Car manufacturers require extreme accuracy. A minor deviation can compromise safety and performance. Traditional machining often fails to achieve the micron-level tolerances needed in car parts manufacturing.

CNC machining for car parts provides unmatched precision. By using automated computer controls, machines deliver exact cuts every time. This reduces rework, saves costs, and ensures reliability for both mass production and custom auto parts.

Speed and Scalability in Car Parts Production

The automotive industry faces tight deadlines and fluctuating demands. Conventional production struggles to balance speed with quality. Delays often cause supply chain issues.

With CNC machining for car parts, production cycles are shorter. Multi-axis machines operate continuously, meeting urgent orders with ease. Businesses benefit from faster delivery without sacrificing accuracy. This scalability helps manufacturers adapt quickly to global market shifts.

Material Versatility and Durability Challenges

Car parts require different materials such as aluminum, steel, and composites. Standard machining cannot handle all these with equal efficiency. Durability suffers when unsuitable techniques are used.

CNC machining works seamlessly across multiple materials. It produces stronger and longer-lasting automotive components. Whether lightweight aluminum for fuel efficiency or steel for structural strength, CNC machining for car parts ensures consistent durability.

High Costs of Traditional Manufacturing

Traditional automotive manufacturing is labor-intensive and prone to errors. Scrap waste and reworks increase costs, affecting profitability.

CNC machining reduces waste with precision programming. Each cut is optimized for material usage. Automated systems lower labor expenses while maintaining consistent quality. This makes CNC machining for car parts a cost-effective long-term solution.

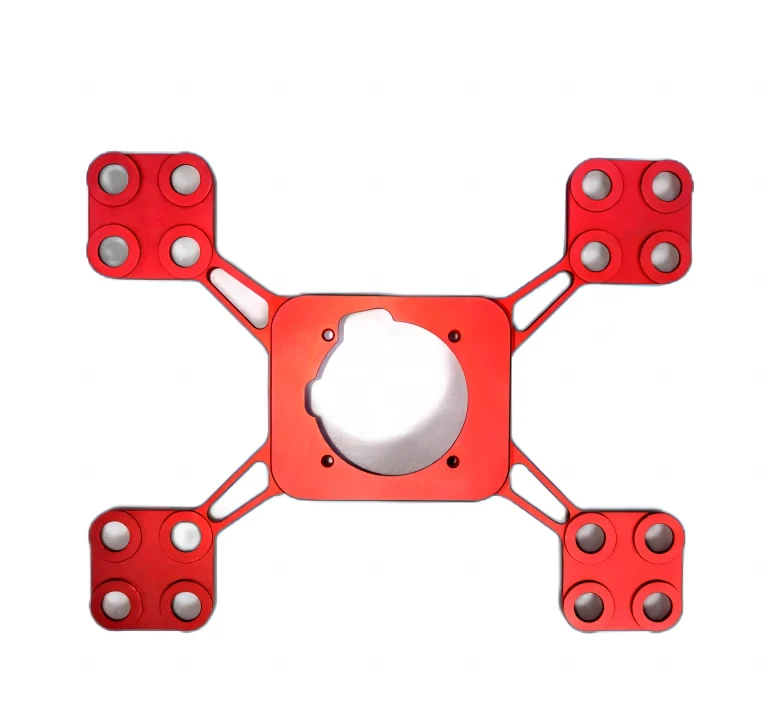

Customization and Complex Designs

Automotive innovation demands unique, complex parts. Traditional processes struggle to achieve intricate geometries. Customization becomes expensive and time-consuming.

CNC machining for car parts supports complex 3D geometries. Engineers can create unique prototypes and scale them quickly. Custom car parts benefit from fast prototyping, making CNC machining essential for innovation.

Technical Solution: CNC Machining for Car Parts

High Tolerance Capabilities

CNC machines operate with tolerances as low as ±0.001 inches. This ensures reliability for components like gears, pistons, and engine blocks.

Faster Production Cycles

Automation allows 24/7 operation, boosting efficiency. One CNC machine can replace multiple traditional tools.

Data-Driven Accuracy

CAD/CAM integration eliminates manual errors. Designs are directly translated into precise manufacturing instructions.

Proven Results

Studies show CNC machining reduces production time by 40% compared to conventional methods. Scrap waste drops by nearly 30%, saving resources.

Why Choose Voguc CNC Machining Services?

For ten years, Voguc has specialized in CNC machining for car parts and industrial applications. We provide:

-

Precision and Speed: Our multi-axis machines ensure tighter tolerances and faster results.

-

Material Expertise: From aluminum to titanium, we deliver durable solutions.

-

Scalable Services: We support both prototypes and bulk orders.

-

Global Reliability: With strong logistics, your parts arrive on time.

-

Sustainability: Our methods reduce waste and comply with eco-friendly standards.

By partnering with Voguc, you gain a reliable team for long-term cooperation. Our CNC machining services enhance your production efficiency and product reliability.

Conclusion

CNC machining for car parts delivers faster production, tighter tolerances, and lower costs. It addresses pain points like precision, scalability, and customization. By choosing Voguc CNC machining services, you ensure reliable solutions backed by over a decade of expertise.

In today’s competitive automotive industry, CNC machining is no longer optional—it is essential. Learn more about our CNC machining product categories and partner with Voguc today and upgrade your manufacturing to the next level.