As the consumer market increasingly shifts toward high customization, downstream manufacturing industries are rapidly boosting their demand. This demand is for multi-variety, small-batch, and high-frequency parts production. Consequently, this trend is propelling CNC custom machining services into the spotlight as a new industry growth point.

Traditional CNC factories have long focused on standardized mass production. However, customer demand has recently shifted sharply. Sectors like 3C electronics, new energy, and medical devices now seek more customized parts. Compared to conventional large-volume orders, these new requests emphasize different priorities. They place greater emphasis on machining flexibility, response speed, and quality control.

“We now handle over 30 new projects per week on average, with most orders consisting of only a few dozen units per model — or even fewer,” said a manager from a precision machining factory in Bao’an, Shenzhen. To meet these evolving needs, the company recently invested in several compact machining centers equipped with quick-change systems and reorganized its scheduling and dispatching strategies.

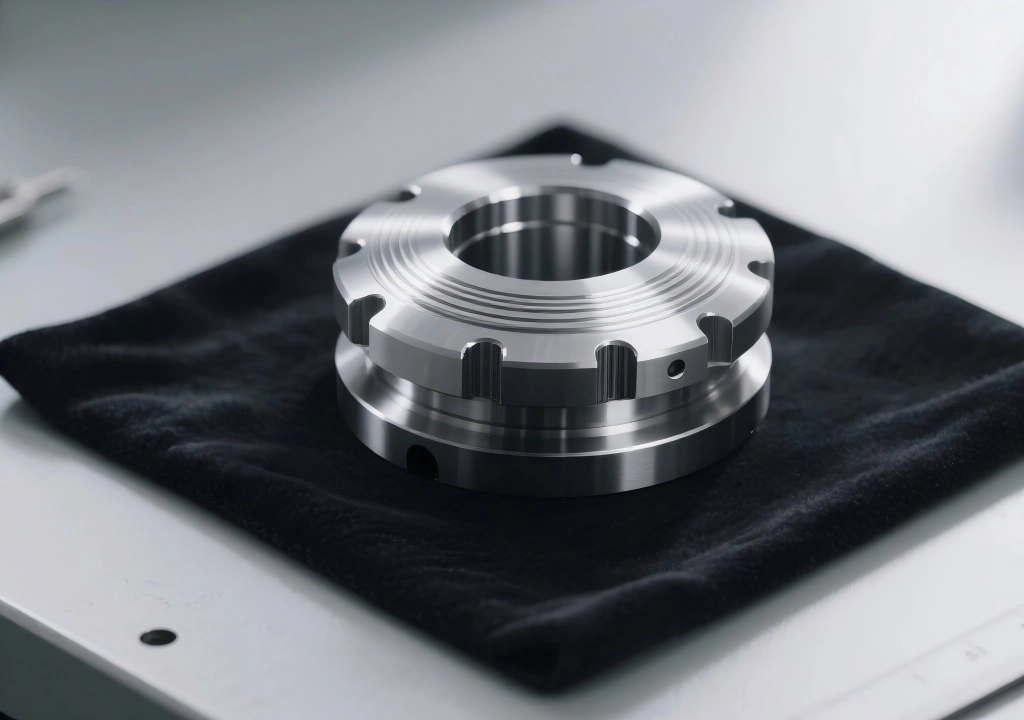

Moreover, some high-end clients now demand full-process traceability, pushing CNC factories to adopt advanced inspection tools such as coordinate measuring machines (CMMs) and laser scanners. These tools allow the production of detailed inspection reports for each part. “Clients are no longer only concerned with price. What matters more to them now are quality, consistency, and delivery reliability,” the manager added.

To meet such diversified demands, some factories are proactively extending their service chains. They now offer one-stop solutions. These solutions cover everything from raw material sourcing to surface treatment and final product assembly. This approach aims to provide more comprehensive support to clients.

According to experts, the next 3 to 5 years will be crucial. During this period, CNC custom machining services will play a vital role in high-end manufacturing. Furthermore, companies that build strong capabilities in flexible production will gain a significant advantage. Additionally, excellence in rapid response and quality assurance is key. Ultimately, these capabilities will help them stand out in the new wave of industrial upgrading.