In the fast-paced world of automotive manufacturing, precision and consistency are the cornerstones of success. As vehicles become more advanced and component tolerances tighter, high-volume automotive CNC production has become a game-changer. It not only ensures accuracy in complex parts but also delivers efficiency, scalability, and quality that manual processes cannot match.

Whether you are an OEM supplier, aftermarket parts manufacturer, or performance tuning company, understanding how CNC technology achieves unmatched precision is key to staying competitive.

The Importance of Precision in Automotive CNC Machining

Why Accuracy Matters in High-Volume Production

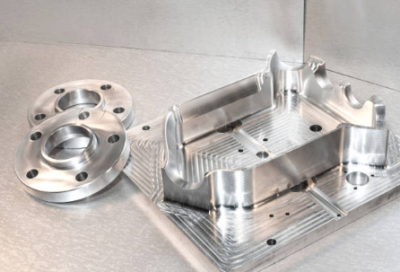

In automotive manufacturing, even the smallest deviation can lead to performance issues or part failure. A single micron-level error could compromise the function of critical components such as:

-

Engine and transmission housings

-

Brake system parts

-

Suspension and steering components

-

Custom performance or racing parts

To maintain consistency across thousands of parts, manufacturers rely on CNC machining centers equipped with advanced feedback and measurement systems.

How High-Volume CNC Production Achieves Unmatched Precision

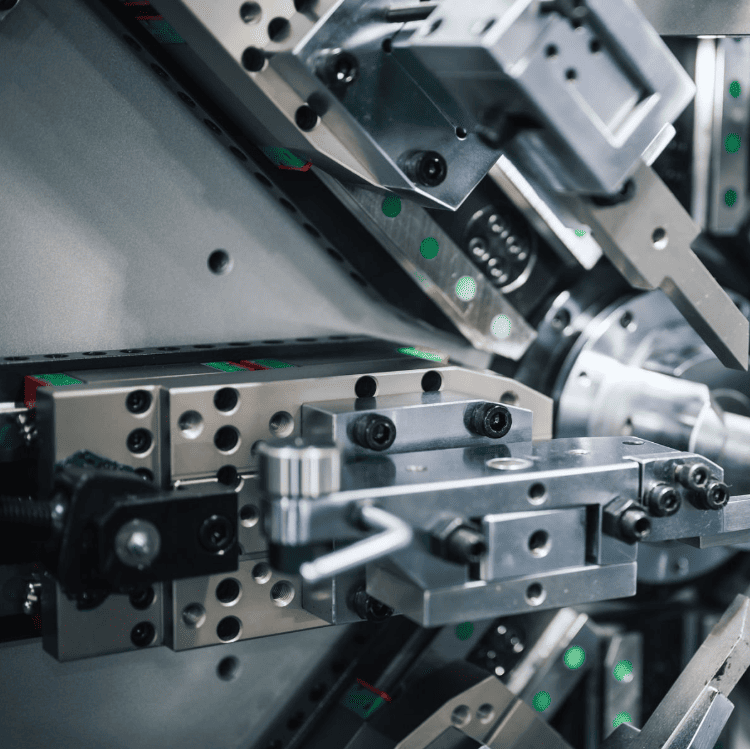

1. Advanced Multi-Axis CNC Machines

Modern 5-axis CNC machines allow simultaneous movement along multiple axes, enabling the creation of complex geometries with extreme accuracy. Each cut and rotation is precisely programmed, ensuring every part matches the CAD model within microns.

2. Automated Tool Calibration and Real-Time Monitoring

Automated systems calibrate tools before and during production. Real-time sensors detect wear and vibration, allowing instant corrections. This automation minimizes human error and ensures consistent results throughout large-scale CNC manufacturing runs.

3. Temperature Control and Material Stability

Temperature fluctuations can alter metal expansion rates, affecting accuracy. High-end CNC facilities like Voguc use controlled environments to maintain material stability during long production cycles—essential for tight-tolerance automotive components.

4. In-Process Quality Inspection

Automated coordinate measuring machines (CMM) and optical inspection tools verify each component mid-cycle. By integrating inspection directly into the production line, high-volume automotive CNC production ensures every part meets design standards before packaging.

The Role of Automation in Large-Scale CNC Manufacturing

Automation isn’t just about speed—it’s about repeatability. When thousands of identical parts are needed, robotic arms, automatic feeders, and AI-driven systems work together to maintain uniformity.

Key benefits include:

-

Continuous operation with minimal downtime

-

Reduced production costs per part

-

Improved tolerance accuracy and consistency

-

Shorter lead times for automotive OEM clients

By combining automation with CNC precision, Voguc helps clients achieve scalable, high-efficiency production while maintaining premium quality.

Applications of High-Volume CNC Machining in the Automotive Sector

1. OEM Vehicle Manufacturing

OEMs rely on CNC machining for critical engine components, ensuring long-term reliability and compliance with international standards.

2. Custom and Performance Car Parts

CNC machining allows for personalized upgrades such as lightweight aluminum parts, racing brackets, and precision brake components—essential for competitive motorsports.

3. Electric Vehicle (EV) Components

As EV adoption grows, high-volume CNC production supports the manufacturing of cooling plates, motor housings, and structural components with tight tolerances for optimal performance.

Why Choose Voguc for High-Volume CNC Production

At Voguc, we specialize in delivering custom CNC car parts with precision and scalability. Our production lines combine advanced automation, real-time quality monitoring, and multi-axis machining to guarantee consistent output.

Our Advantages:

-

ISO 9001-certified precision machining processes

-

±0.001 mm tolerance capability

-

High-speed 5-axis CNC centers for complex geometries

-

Rapid prototyping and mass production support

-

End-to-end project management and global delivery

Whether you need a few prototypes or high-volume CNC car parts, Voguc provides end-to-end manufacturing solutions that drive your business forward.

How Precision CNC Machining Improves Cost Efficiency

Precision doesn’t just enhance quality—it saves money. Automated CNC processes reduce waste material, minimize rework, and ensure faster setup for large batches.

Voguc’s integrated approach helps clients achieve:

-

Lower per-unit costs for mass production

-

Improved turnaround times

-

Enhanced part reliability and customer satisfaction

Conclusion:

As the automotive industry evolves, high-volume CNC machining remains the foundation of precision manufacturing. From complex engine components to lightweight racing parts, it ensures consistent quality, dimensional accuracy, and cost efficiency at scale.

Choosing a reliable partner like Voguc ensures you benefit from world-class CNC expertise, global delivery, and manufacturing excellence that drives your automotive business into the future.

Frequently Asked Questions (FAQ)

1. What is the main advantage of high-volume CNC production for automotive parts?

It ensures consistency and precision across large batches, reducing errors and production costs.

2. Can Voguc handle both prototyping and mass production?

Yes. Voguc offers flexible CNC machining solutions—from prototype testing to full-scale production.

3. How does Voguc maintain tight tolerances in high-volume runs?

By combining 5-axis CNC technology, real-time monitoring, and automated inspection systems for every batch.