Are your medical implants meeting the strictest safety codes? 🛑 Substandard components lead to tragic surgical failures today. Many manufacturers face recalls due to tiny micro-defects now. Specifically, implants require absolute surface perfection and accuracy. You need a medical device milling parts supplier you can trust. Finding an elite partner is critical for your patient safety. Do not settle for general machine shops for medical gear. Discover the essential vetting steps for high-stakes medical projects. 🚀 Your journey to surgical excellence starts right here today. Let us explore the world of medical-grade precision together.

The Technical Mastery of Medical Milling 🔬

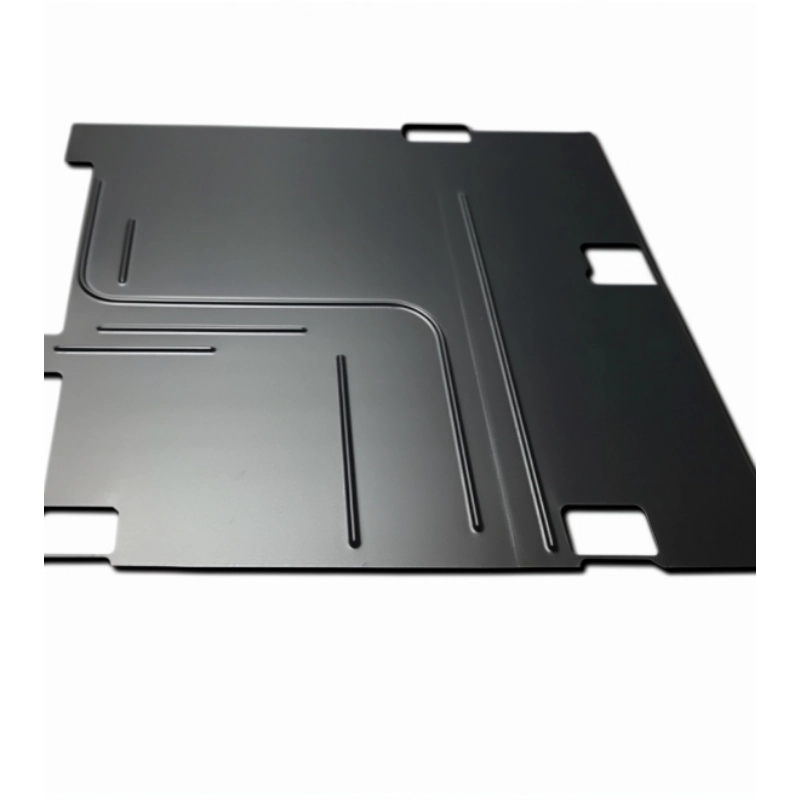

A specialized medical device milling parts supplier understands unique risks. They do not just cut metal for your devices. Specifically, they master tough materials like Titanium and PEEK. These materials require specific speeds and cooling techniques now. Furthermore, 5-axis CNC machining ensures complex geometric accuracy today. This technology allows for seamless, one-piece implant designs. 💡 Elite suppliers also maintain strict cleanroom environments for parts. This prevents oil or dust contamination during the process. Consequently, you receive parts ready for immediate sterilization. Every micron matters when a device enters a human body. Technology must meet the highest human biological standards now.

The Non-Negotiable ISO 13485 Certification 🛡️

Why is ISO 13485 the most important document today? A certified medical device milling parts supplier follows strict quality laws. They provide full traceability for every raw material batch. This ensures you know the exact source of your metal. Moreover, it proves their quality management meets global medical rules. You get consistent results across every production run. Therefore, never skip this credential during your initial vetting.

Advanced Surface Finishing and Biocompatibility ✨

Quality extends beyond the initial cutting of the part. Your medical device milling parts supplier must offer specialized finishes. Specifically, electropolishing removes microscopic burrs from surgical surfaces. Modern shops use laser inspection to verify surface roughness. These tools ensure the part is perfectly smooth and safe. Consequently, the implant integrates better with human bone tissue. Superior finishing is the mark of a medical expert.

Achieve Market Leadership with Total Compliance 🏆

Imagine launching your new implant with total clinical confidence. 🌟 Your surgeons praise the perfect fit of your tools. Using an elite medical device milling parts supplier makes this real. You no longer fear the stress of FDA audits. ✨ Instead, you focus on your next medical breakthrough. Experience the professional pride of delivering life-changing medical tech. 🌟 Your brand will become a synonym for surgical reliability. Better parts lead to faster healing for every patient. High-quality milling turns your designs into industry gold. You deserve a partner that respects your life-saving mission. Reach new clinical heights with a team that delivers.

Why Leading Med-Tech Firms Choose Elite Standards? 📈

Reliable manufacturing is the heart of the medical industry. See why these standards protect your brand and patients:

-

Material Certification: We provide mill reports for all medical-grade alloys.

-

Validation Support: We help you complete your IQ/OQ/PQ processes.

-

Micro-Milling Capability: We handle features smaller than a human hair.

-

Zero-Defect Culture: Every part undergoes a rigorous 100% inspection.

-

Scalable Growth: We move from R&D prototypes to mass production.

Start Your Medical Vetting Process Today 🛒

The demand for better medical outcomes grows every day. Do not let a weak supplier risk your company. Explore the best medical device parts supplier solutions now. Get a free professional DFM audit for your implant. 📦 Our team will review your drawings for medical feasibility. We offer flexible options for micro-milling and specialized coatings. Improve your device safety and lower your regulatory risk. 🛒 Take the first step toward medical innovation right now. Contact a specialized medical fabrication team for a quote today.

Ready to Elevate Your Medical Device Quality? ✅

-

Upload your CAD files to our secure medical portal.

-

Specify your biocompatibility and surface finish requirements today.

-

Access 5-axis technology for your most complex implant designs.

-

Review a detailed compliance and production timeline for parts.

-

Start your first validated run and experience true precision.

Visit our official site to browse our medical gallery. Read testimonials from surgeons who trust our precision systems. Find the perfect balance between high-tech and absolute safety. The future of your medical device depends on quality. Contact us today to secure your clinical success! 🖱️✨

Trust is the Most Critical Component 🏁

In 2026, medical success requires more than just good ideas. A great medical device milling parts supplier provides clinical safety. They protect your reputation and save lives every day. Make your production as precise as a surgeon’s hand. Your global medical success begins with a perfect part. 🥂

FAQ

1. Which materials do you recommend for long-term implants?

Titanium Grade 5 and PEEK are the top choices today. They offer the best biocompatibility and strength for human use. A skilled medical device milling parts supplier knows how to handle these. They ensure no metallic contamination occurs during the milling process. 🦴

2. How do you ensure 100% part traceability?

We assign a unique batch code to every raw material. This code follows the part through every single milling stage. We provide full documentation for your permanent medical device files. This makes your FDA or CE marking process much smoother. 📋

3. Can you handle micro-milling for neurosurgery tools?

Yes, we use ultra-high-speed spindles for tiny surgical components. We can maintain tolerances as tight as +/- 0.005mm easily. This precision is vital for tools used in brain surgery. Trust our micro-milling experts for your most delicate medical projects. 🧠