Our copper turned parts for aircraft engines are engineered with precision and reliability to meet the demanding requirements of the aerospace industry. Manufactured using advanced CNC turning technology, these components ensure tight tolerances, excellent conductivity, and superior mechanical strength—critical for optimal performance in high-temperature and high-stress engine environments.

We utilize premium-grade copper materials that comply with strict aerospace standards, offering outstanding durability, resistance to wear, and efficient thermal and electrical conductivity. Each part undergoes rigorous quality inspection, ensuring consistent performance and long-term reliability in mission-critical applications.

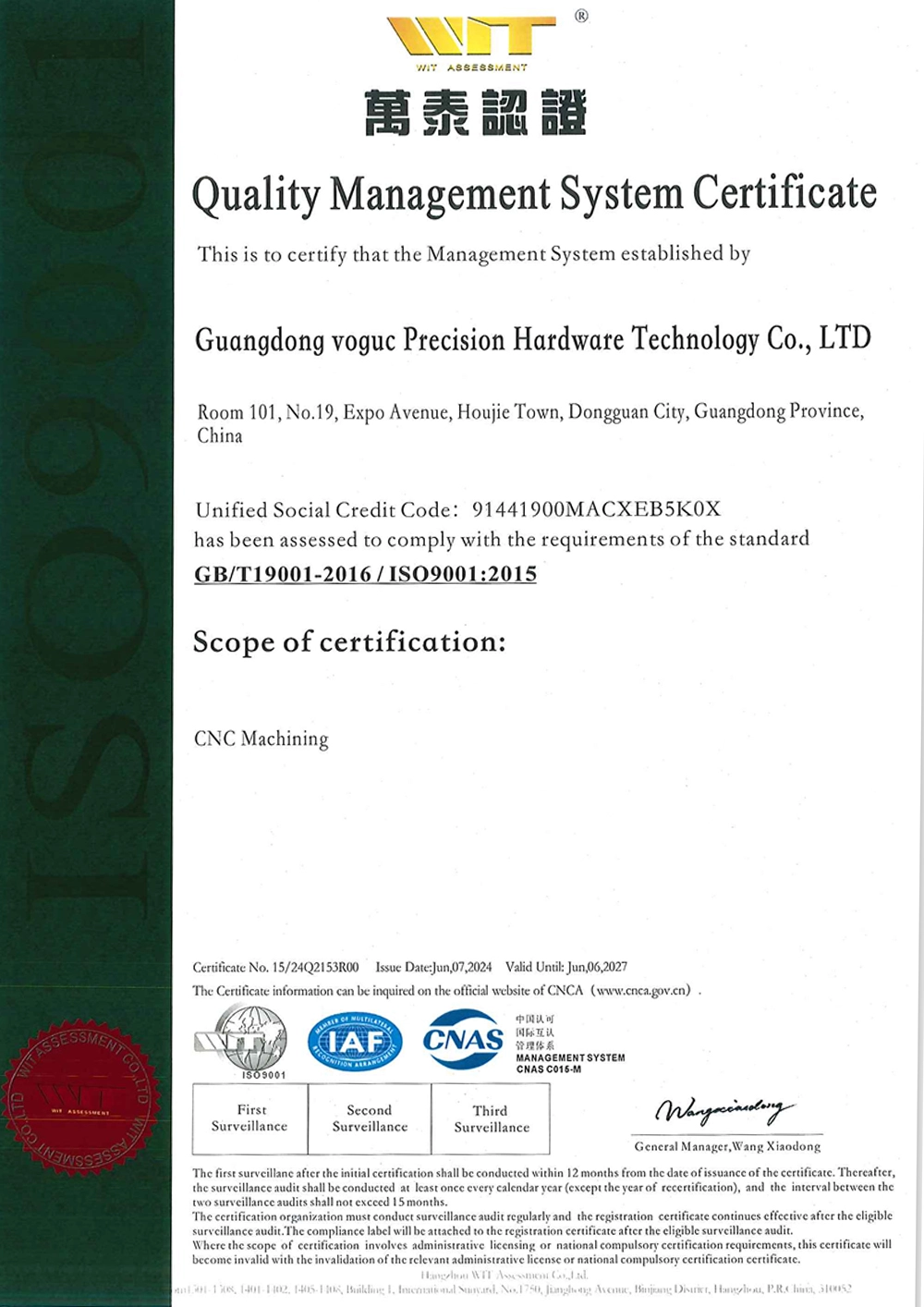

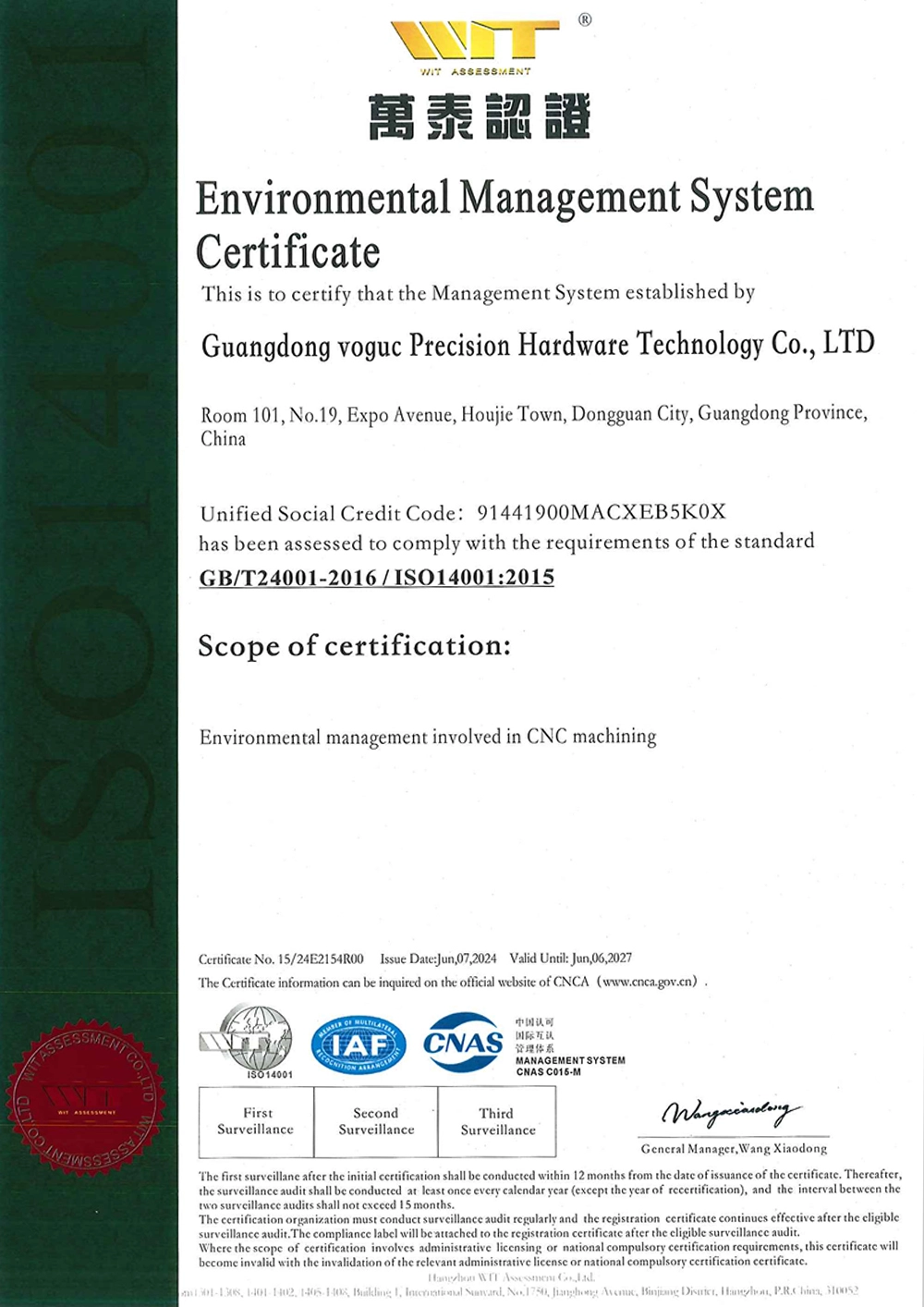

Whether you need custom prototypes or large-scale production, our expertise in CNC machining for aerospace components guarantees parts that meet ISO and AS9100 quality standards.

✔ High-precision CNC turned copper components

✔ Excellent conductivity for engine performance

✔ Durable and compliant with aerospace standards

✔ Custom sizes and designs available on request

Enhance the reliability of your aircraft engines with our precision copper turned parts. Contact us today for a custom quote and technical consultation tailored to your aerospace needs!

Parameter of(Copper turned parts for aircraft engines)

| Item | Customized according to customer requirements |

| Volume | |

| Surface finish | |

| Material | |

| Weight | |

| Applicable standards | |

| Other requirements |

Advantage of (Copper turned parts for aircraft engines)

This component is used in aircraft engines and must maintain high quality to ensure proper engine operation and extend its service life.

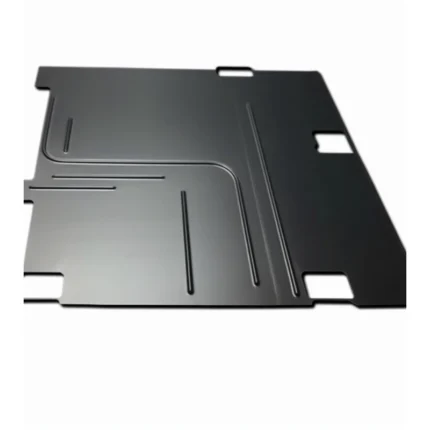

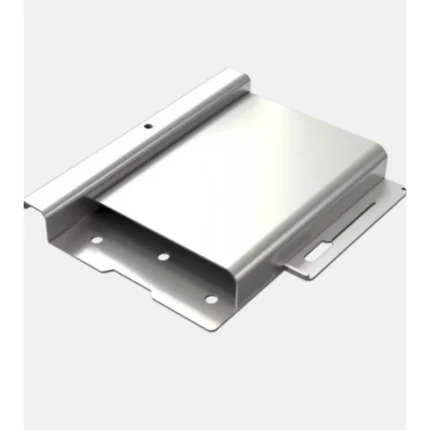

Image of (Copper turned parts for aircraft engines)

Looking for your inquiry of this (Copper turned parts for aircraft engines)

FAQ

A: We work with a wide range of metals and plastics, including aluminum, stainless steel, brass, copper, titanium, POM, and more.

A: Yes, we specialize in custom machining based on customer-provided drawings or 3D models.

A: We accept STEP, IGES, STL, PDF, and DWG formats.

A: Standard lead time is 7–15 working days, depending on part complexity and order quantity.

A: Yes, we provide anodizing, sandblasting, electroplating, powder coating, polishing, and more.

A: We do not have a strict MOQ—prototypes and small batches are welcome.

A: Yes, we offer mechanical assembly services if required.

Services

1. Quote within one business day upon receipt of drawings and requirements

2. Transparent production process, allowing you to monitor production progress at any time

3. Customizable shipping methods

Reviews

There are no reviews yet.