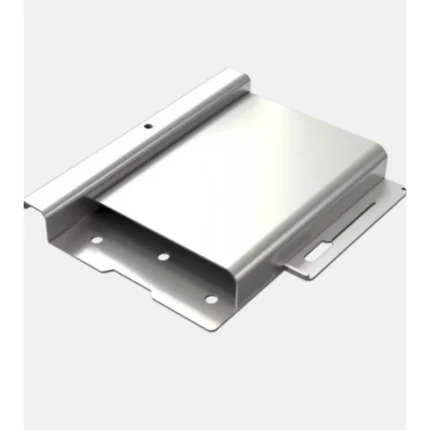

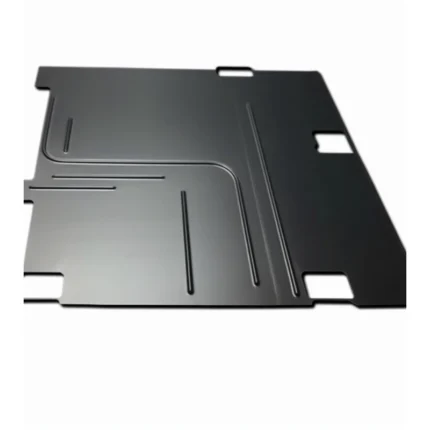

Reliable and Durable Mold Components

Enhance your tooling performance with our precision ground parts for mold cavities. Built with strict tolerances and smooth finishes, these components ensure high stability, long service life, and consistent product quality in injection molding and die-casting applications.

High-Accuracy Grinding Process

Each part is manufactured using advanced CNC grinding technology. With dimensional accuracy up to ±0.01mm and polished surfaces, they guarantee precise cavity formation. This reduces defects and ensures seamless part ejection, even under high-volume production conditions.

Optimized for Mold Performance

Our ground parts improve cavity strength, wear resistance, and thermal stability. By minimizing surface roughness, they reduce friction during molding, extending tool life while maintaining excellent product consistency across multiple cycles.

Versatile Applications

These precision ground mold cavity parts are suitable for plastic injection molds, die-casting molds, and precision tooling. They are widely used in industries such as automotive, electronics, consumer products, and medical device manufacturing.

Factory Supply and Competitive Pricing

We provide direct factory supply with customizable options, from prototype samples to bulk orders. With consistent quality, fast delivery, and competitive pricing, our ground mold cavity parts are the ideal choice for global manufacturers seeking efficiency and reliability.

Parameter of(Ground parts for mold cavities)

| Item | Customized according to customer requirements |

| Volume | |

| Surface finish | |

| Material | |

| Weight | |

| Applicable standards | |

| Other requirements |

Advantage of (Ground parts for mold cavities)

This component is used in mold cavities and must maintain high precision to ensure the accuracy of the mold dimensions.

Image of (Ground parts for mold cavities)

Looking for your inquiry of this (Ground parts for mold cavities)

FAQ

A: We work with a wide range of metals and plastics, including aluminum, stainless steel, brass, copper, titanium, POM, and more.

A: Yes, we specialize in custom machining based on customer-provided drawings or 3D models.

A: We accept STEP, IGES, STL, PDF, and DWG formats.

A: Standard lead time is 7–15 working days, depending on part complexity and order quantity.

A: Yes, we provide anodizing, sandblasting, electroplating, powder coating, polishing, and more.

A: We do not have a strict MOQ—prototypes and small batches are welcome.

A: Yes, we offer mechanical assembly services if required.

Services

1. Quote within one business day upon receipt of drawings and requirements

2. Transparent production process, allowing you to monitor production progress at any time

3. Customizable shipping methods

Reviews

There are no reviews yet.