In the automotive industry, precision and quality are non-negotiable. Whether it’s for performance parts, aesthetic features, or functional components, custom vehicle parts must meet high standards for safety, durability, and fit. Automotive CNC manufacturing solutions provide the ideal solution.

CNC (Computer Numerical Control) machining has revolutionized manufacturing. It offers a level of precision and versatility that traditional methods can’t match. In this article, we’ll explore why CNC machining is the best choice for custom vehicle parts and how it benefits manufacturers and end-users.

What Are Automotive CNC Manufacturing Solutions?

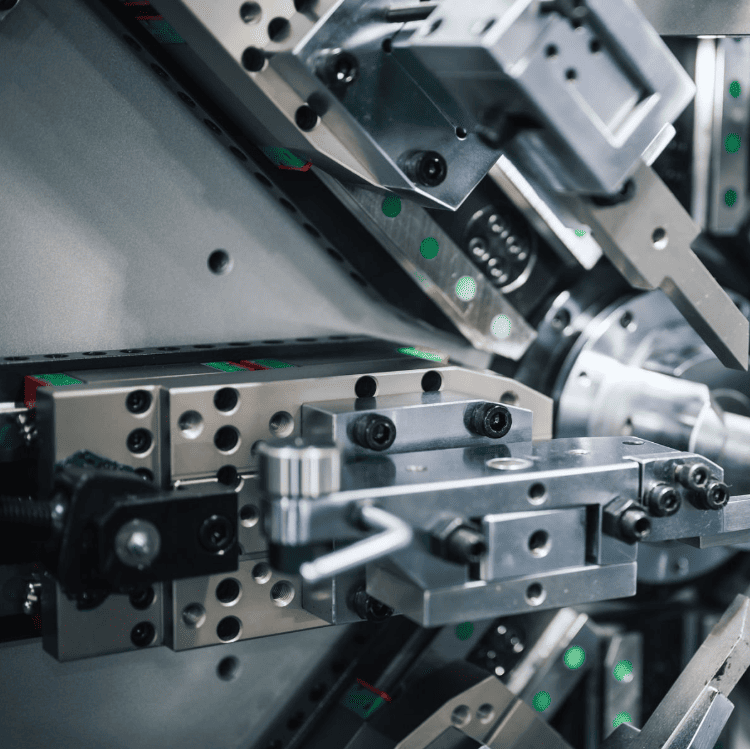

Automotive CNC manufacturing solutions use CNC technology to create vehicle parts with extreme precision. CNC machines automate the process of shaping, cutting, and finishing parts from metals or plastics. This technology allows for complex designs and tight tolerances with minimal human intervention.

Compared to traditional methods, CNC machining reduces material waste, speeds up production, and achieves intricate designs. Whether for engine parts, suspension components, or custom trims, CNC machining offers accuracy and efficiency.

Key Benefits of Using CNC for Custom Vehicle Parts

1. Unmatched Precision and Accuracy

Automotive CNC manufacturing solutions ensure unmatched precision. Traditional machining methods can lead to human error and inconsistencies. CNC machines follow computer-controlled instructions, guaranteeing each part is made to exact specifications.

-

Tight Tolerances: CNC machines can create parts with tight tolerances, ensuring a perfect fit.

-

Repeatable Accuracy: CNC machining consistently produces identical parts every time.

For custom vehicle parts, this precision is vital for parts that must fit and perform as intended.

2. Flexibility in Design and Customization

Custom vehicle parts often require unique shapes and sizes. Traditional manufacturing methods can be time-consuming and costly. CNC machining for vehicles solves this by offering exceptional flexibility, enabling the production of one-off or limited-run parts.

-

Complex Geometries: CNC machines handle highly complex designs easily.

-

Rapid Prototyping: CNC machining speeds up prototype creation, helping designers move from concept to production faster.

This flexibility allows for innovative designs that meet the specific needs of the automotive industry.

3. Cost-Effectiveness for Low and High-Volume Production

Although CNC machining for vehicles may have higher initial setup costs, it proves to be cost-effective, especially for low and medium-volume production. Once programmed, CNC machines produce parts quickly with minimal manual labor.

-

Lower Labor Costs: CNC machines operate autonomously, reducing the need for manual labor.

-

Reduced Material Waste: CNC machines use materials efficiently, lowering production costs.

CNC machining offers cost savings whether you’re making one custom part or thousands.

4. Enhanced Durability and Quality

Custom vehicle parts must meet stringe

-

Stronger Parts: CNC machining produces parts free of defects, ensuring durability.

-

Consistent Quality: Every part is identical, maintaining the same high-quality standards.

CNC machining consistently produces parts that meet or exceed durability and safety requirements.

5. Faster Turnaround Times

In the automotive industry, quick turnaround times are essential. CNC machining for vehicles accelerates production and reduces lead times, getting custom parts to market faster.

-

Faster Production: CNC machines work efficiently, producing large quantities of parts in less time.

-

Quick Adjustments: Modifying designs is easy, making CNC machining perfect for rapid development.

The speed of CNC machining ensures that manufacturers can meet tight deadlines and market demands.

Conclusion:

Automotive CNC manufacturing solutions are transforming how custom vehicle parts are designed, produced, and delivered. With benefits such as precision, flexibility, cost-effectiveness, and quality, CNC machining is the ideal solution for the automotive industry. Whether you’re making one-off components or high-volume production parts, CNC machining ensures efficiency and reliability.

At Voguc, we specialize in providing CNC manufacturing solutions for the automotive industry, helping you create custom parts with the precision and reliability you need.

FAQ:

1. How does CNC machining ensure accuracy in custom vehicle parts?

CNC machining uses computer-controlled tools that follow precise instructions, eliminating human error and ensuring each part meets exact specifications.

2. Is CNC machining cost-effective for low-volume production?

Yes, CNC machining is cost-effective for both low and high-volume runs. It reduces labor costs, minimizes material waste, and speeds up production.

3. What types of custom vehicle parts can be made with CNC machining?

CNC machining can create a wide variety of vehicle parts, including engine components, suspension parts, brackets, and trim pieces, all with high precision.