Medical device precision machining is essential for compliance with global regulations and patient safety. Industries must follow strict standards, including ISO 13485 and FDA guidelines, to ensure medical devices are safe, reliable, and lead-free compliance ready.

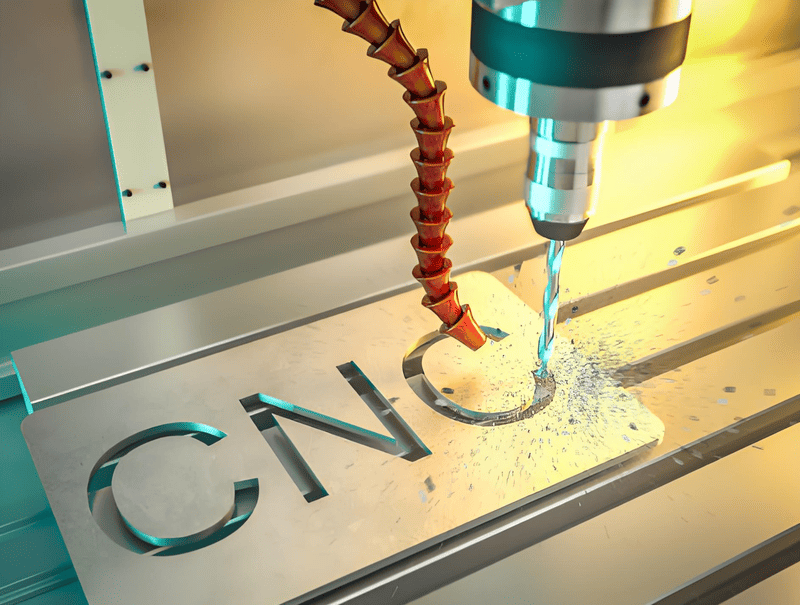

At Voguc, with over 11 years of CNC machining experience, we specialize in medical device precision machining alongside aerospace, automotive, and UAV components.

Regulatory Compliance Risks

Medical device manufacturers face strict regulations worldwide. Non-compliance can result in recalls, penalties, and reputational damage. Standard machining suppliers often lack the expertise to meet ISO and FDA requirements.

With professional medical device precision machining, compliance is guaranteed. Voguc ensures every part follows global regulations, minimizing compliance risks.

Inconsistent Accuracy in CNC Medical Components

Even minor deviations in precision CNC parts can cause device malfunction. For implants and surgical tools, tolerances must be extremely tight. Inconsistent machining leads to wasted materials and higher costs.

Our CNC machining services achieve ±0.01mm tolerance for medical device components. This level of accuracy ensures patient safety and long-term device reliability.

Material Compatibility Challenges

Medical devices require specialized materials like titanium, stainless steel, and biocompatible plastics. Not all machining providers can handle these materials with the required expertise.

At Voguc, we handle a wide range of biocompatible materials. Our CNC machining medical components are designed for durability and compliance with industry standards.

Slow Production and Delays

Delays in producing medical device components can disrupt entire supply chains. Hospitals and clinics cannot afford late deliveries, especially for urgent medical needs.

An experienced OEM CNC machining manufacturer like Voguc uses lean workflows and advanced scheduling to guarantee timely delivery. We balance precision and speed to meet deadlines without compromise.

Lack of Industry-Specific Expertise

General machining providers may not fully understand the complexities of medical device compliance. Without industry knowledge, errors in documentation or inspection processes increase.

With Voguc’s 11 years of experience, our medical device precision machining aligns with ISO 13485 quality standards. This expertise ensures safe, compliant, and reliable outcomes.

Technical Solutions for Medical Device Precision Machining

Tight Tolerance Capabilities

Medical devices require exact measurements. Voguc uses advanced 5-axis CNC machining to deliver precision CNC parts with tight tolerances.

Regulatory Standard Integration

We align CNC machining services with ISO 13485 and FDA requirements. Every component undergoes thorough inspection to ensure compliance and safety.

Biocompatible Materials Expertise

Our medical device precision machining processes handle titanium, stainless steel, and high-grade plastics. This ensures compatibility with patient safety needs.

Automated Quality Control

Using digital measuring systems, every CNC part is validated before delivery. Automated systems reduce human error and improve compliance reporting.

Scalable Production

Whether prototypes or mass production runs, Voguc provides scalable CNC machining medical components. This flexibility supports fast innovation cycles in the medical sector.

Why Choose Voguc for Medical Device Precision Machining?

Voguc is a trusted CNC machining services provider with deep industry experience. Our team delivers more than just parts—we provide compliance-driven solutions.

-

11 years of CNC machining experience

-

Expertise in medical, automotive, aerospace, and UAV components

-

±0.01mm tolerance for precision CNC parts

-

ISO 13485-aligned medical device precision machining

-

Tailored solutions for custom medical projects

Choosing Voguc means gaining a partner committed to compliance, safety, and innovation.

The Advantages of a Professional CNC Machining Partner

-

Safety – Reliable CNC machining medical components prevent device failures.

-

Compliance – Processes aligned with ISO and FDA regulations.

-

Customization – Tailored designs for unique medical device needs.

-

Efficiency – Faster workflows with lean production systems.

-

Scalability – Flexibility from prototype to full production.

By partnering with a professional OEM CNC machining manufacturer, you minimize risks and ensure long-term success.

Final Thoughts

Medical device precision machining is critical for compliance and patient safety. From implants to surgical tools, accuracy and reliability define success.

At Voguc, we combine 11 years of experience, advanced CNC machining technology, and a proven record of compliance. Our CNC machining services ensure custom, biocompatible, and compliant medical components.

Choose Voguc as your trusted partner for medical device precision machining. With our expertise, you secure quality, compliance, and efficiency for every project.

Explore our product category or check our guide today to discover how Voguc can support your next custom medical device project.